1. Introduction to High Pressure Pumps

In the realm of industrial equipment and components, **industrial high pressure pumps** play a pivotal role. These pumps are designed to move fluids at significantly increased pressures, making them essential for various applications across multiple industries. From chemical processing to oil and gas exploration, a **high pressure pump** is a vital asset that ensures optimal performance and productivity.

As industries continue to evolve, the demand for durable and reliable pumping solutions has grown. The focus on durability not only enhances operational efficiency but also significantly reduces downtime and maintenance costs. In this guide, we will delve deeper into the various benefits of **durable high pressure pumps**, exploring their impact on industrial applications.

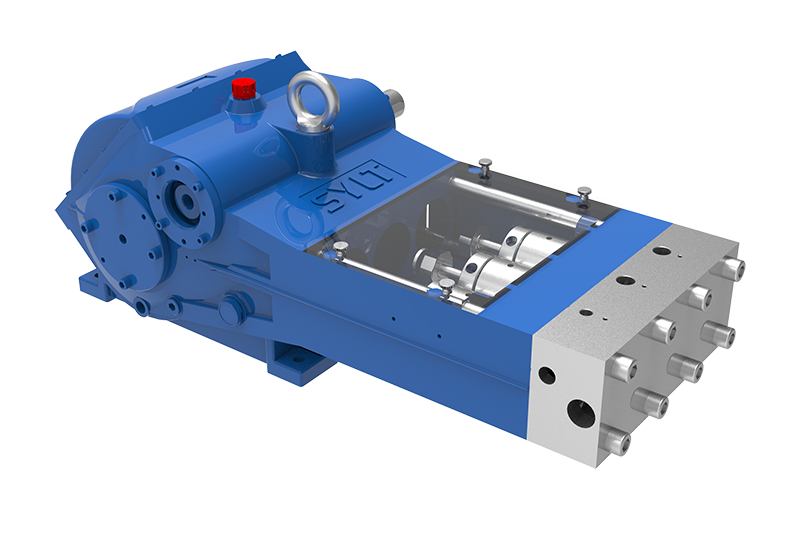

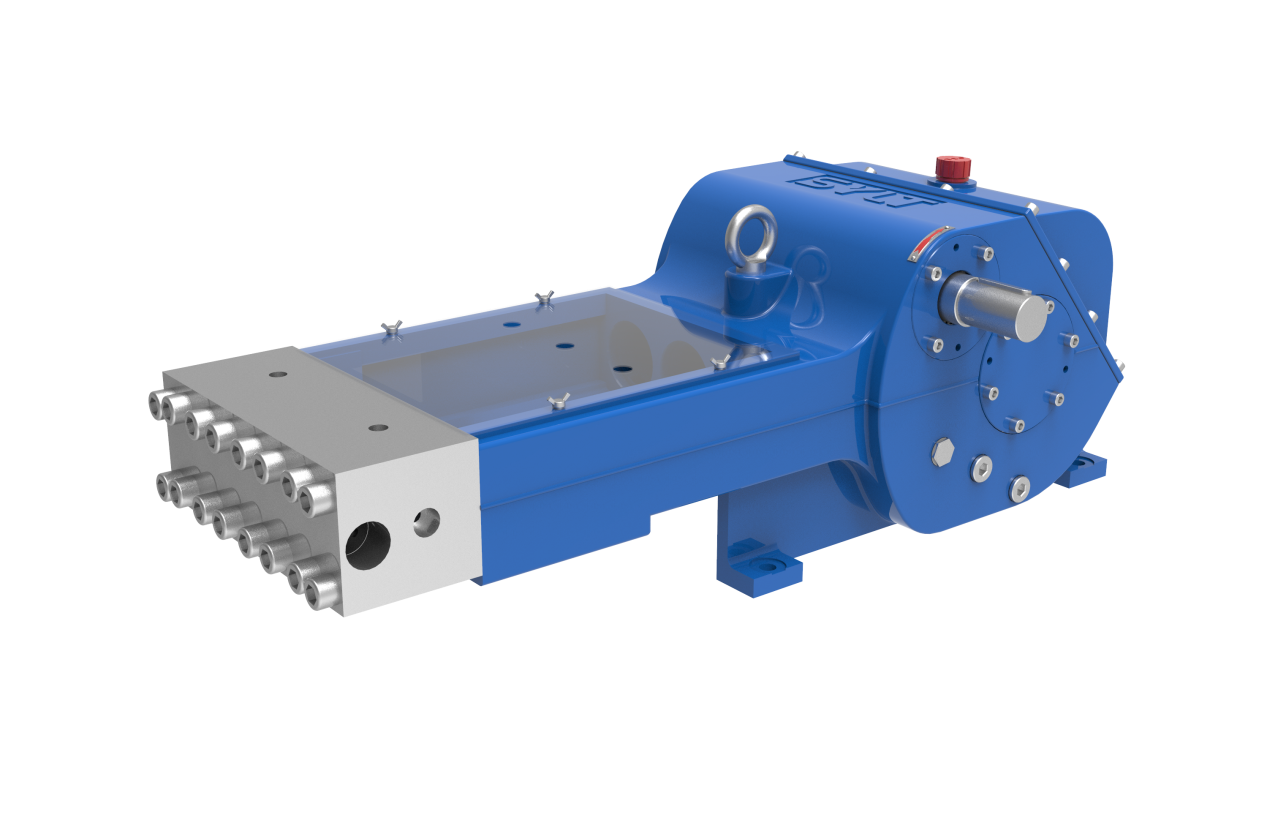

2. Understanding High Pressure Pumps

High pressure pumps are engineered to generate pressure that exceeds standard atmospheric levels, allowing them to transport fluids ranging from water to highly viscous liquids. These pumps are characterized by their robust construction, which enables them to handle the demands of industrial environments.

Types of High Pressure Pumps

There are several types of high pressure pumps, each tailored for specific applications:

- **Positive Displacement Pumps:** These pumps move fluid by trapping a fixed amount and forcing it into the discharge pipe. They are commonly used for precise applications.

- **Centrifugal Pumps:** Utilizing rotational kinetic energy, centrifugal pumps are ideal for transferring large volumes of fluid at lower pressures.

- **Diaphragm Pumps:** Known for their ability to handle corrosive fluids, diaphragm pumps are perfect for chemical industries.

###

Features of Durable High Pressure Pumps

Durable high pressure pumps often incorporate advanced features:

- **Corrosion-Resistant Materials:** Many pumps are made from stainless steel or specialized alloys to withstand harsh environments.

- **Sealed Mechanisms:** Enhanced sealing helps prevent leaks and contamination.

- **Variable Speed Drives:** These allow for adjustments in flow rates, optimizing energy consumption and pump performance.

3. Key Applications in Industrial Settings

High pressure pumps are indispensable in numerous industrial applications. Some notable uses include:

- **Hydraulic Systems:** In construction and manufacturing, these pumps power hydraulic equipment.

- **Water Jet Cutting:** Utilized in precision cutting processes, high pressure water jets can slice through materials with incredible accuracy.

- **Chemical Processing:** High pressure pumps safely transport hazardous and non-hazardous fluids, ensuring stringent safety protocols are met.

- **Oil and Gas Extraction:** These pumps facilitate the movement of crude oil and other fluids in extraction and refining processes.

4. Benefits of Durability

Durability in high pressure pumps translates directly to operational advantages. The following points illuminate why investing in a durable pump is crucial for industrial applications:

###

Extended Lifespan

Durable pumps are built to withstand rigorous operating conditions, which significantly extends their lifespan. This quality reduces the need for frequent replacements, allowing companies to focus resources on production rather than maintenance.

###

Reduced Maintenance Costs

A robust design minimizes wear and tear, leading to lower maintenance costs over time. This cost-effectiveness is critical for companies aiming to maintain profit margins while ensuring high productivity levels.

###

Consistent Performance

Durable high pressure pumps maintain performance standards even under high stress. Consistency in performance is essential for processes requiring precision and reliability, particularly in high-stakes industries like pharmaceuticals and aerospace.

5. Enhanced Efficiency and Productivity

Investing in a durable high pressure pump can significantly enhance operational efficiency, leading to increased productivity.

###

Optimized Fluid Transfer

High pressure pumps facilitate faster and more efficient fluid transfer, reducing cycle times in production. This efficiency allows industries to scale their operations without compromising quality.

###

Energy Savings

Modern durable high pressure pumps often feature energy-efficient designs, which consume less energy while delivering optimal performance. This translates to significant cost savings in energy bills for industrial operations.

###

Improved Process Control

Advanced pumps with variable speed capabilities allow for precise control over flow rates. This control is essential for applications that require specific conditions for optimal product quality.

6. Cost-Effectiveness Over Time

While the initial investment in durable high pressure pumps may be higher compared to standard pumps, the long-term cost-effectiveness is undeniable.

###

Lower Total Cost of Ownership

The total cost of ownership encompasses the purchase price, maintenance, and operational expenses over the pump's lifespan. Durable pumps reduce total ownership costs by minimizing repairs and enhancing efficiency.

###

Increased Productivity Leads to Higher Revenue

With enhanced productivity, companies can increase output without the need for additional resources, leading to higher revenue generation. This efficiency is a crucial factor in maintaining a competitive edge in the market.

7. Safety and Reliability Factors

Safety is paramount in industrial applications, and durable high pressure pumps contribute significantly to operational safety.

###

Reduced Risk of Malfunction

Durable pumps are less likely to malfunction, which can pose risks to worker safety and equipment integrity. This reliability is particularly vital in hazardous environments, such as chemical processing plants.

###

Enhanced Safety Features

Many modern high pressure pumps incorporate safety features such as pressure relief valves and automatic shut-off mechanisms. These features protect both the equipment and personnel working in proximity to the pumps.

8. Choosing the Right High Pressure Pump

Selecting the appropriate high pressure pump for your application requires careful consideration of various factors:

###

Assessing Application Requirements

Evaluate the specific needs of your application, including the type of fluid being pumped, required pressure levels, and flow rate. This assessment will guide you in selecting a pump that meets operational demands.

###

Consulting with Experts

Engaging with industry experts can provide valuable insights into the best pump options available. They can help identify the most suitable models based on your unique needs and budget constraints.

###

Considering Total Cost of Ownership

When evaluating pumps, consider not only the purchase price but also the potential maintenance and operational costs. Investing in a durable pump may offer greater value in the long run.

The utilization of durable high pressure pumps in industrial applications offers a plethora of benefits, including enhanced efficiency, safety, and cost-effectiveness. Investing in high-quality pumps not only improves productivity but also ensures a reliable operation that can withstand the rigors of industrial environments. As industries continue to prioritize durability and performance, high pressure pumps will remain an essential component in driving success and innovation within various sectors. By choosing the right pump and understanding its advantages, companies can optimize their operations and achieve sustainable growth in an increasingly competitive landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.