A Deep Dive into Advanced High Pressure Pumps: Essential Features You Can't Overlook

High pressure pumps are critical components in various industries, providing the necessary force to move fluids efficiently under high pressure. In this article, we will explore the advanced features of high pressure pumps, discussing how these elements can significantly enhance operational efficiency and reliability. Understanding these features is crucial for making informed decisions when selecting the right high pressure pump for your specific application.

Table of Contents

- What Are High Pressure Pumps?

- The Importance of High Pressure Pumps in Industries

- Advanced Features of High Pressure Pumps

- Energy Efficiency for Cost Savings

- Material Compatibility and Durability

- Flow Rate Accuracy and Consistency

- Technology Integration for Enhanced Performance

- Simplicity of Maintenance and Service

- Applications of High Pressure Pumps

- Choosing the Right High Pressure Pump

- Frequently Asked Questions (FAQs)

- Conclusion

What Are High Pressure Pumps?

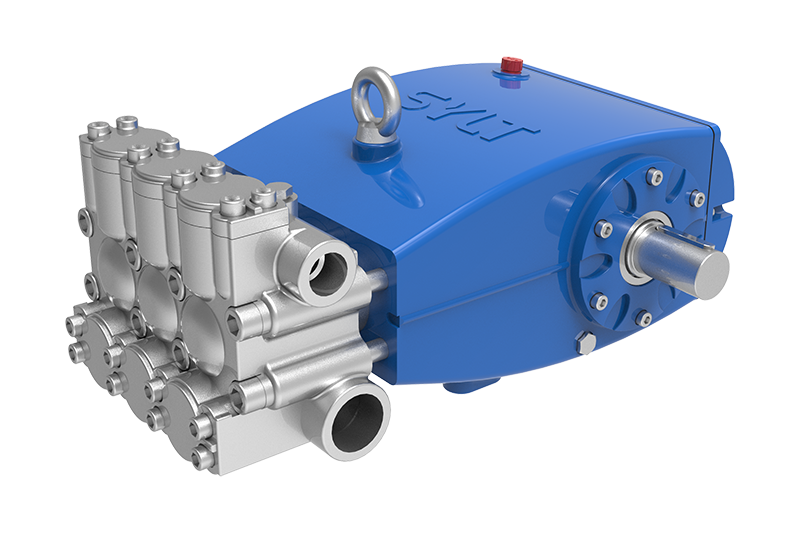

High pressure pumps are specialized devices designed to move fluids at significantly elevated pressures, often exceeding 100 psi. These pumps are utilized in various applications, including industrial processes, water treatment, and chemical manufacturing. They are engineered to handle a wide range of fluids, including water, oils, and corrosive substances, making them versatile tools in modern engineering.

The Importance of High Pressure Pumps in Industries

The significance of high pressure pumps cannot be overstated. They play a crucial role in enhancing productivity, ensuring efficient fluid transfer, and maintaining the continuity of processes in manufacturing and production environments. Their ability to generate high pressure is vital in applications such as:

- Hydraulic Systems: Powering machinery and tools.

- Water Jet Cutting: Precision cutting of materials.

- Chemical Processing: Moving hazardous materials safely.

- Oil and Gas: Extraction and transportation of resources.

Advanced Features of High Pressure Pumps

When considering high pressure pumps, it is essential to evaluate their advanced features that enhance performance, reliability, and efficiency. Here are some key features you should not overlook:

Energy Efficiency for Cost Savings

Energy efficiency is a key factor when choosing high pressure pumps. Advanced models are designed to minimize energy consumption while maximizing output. By employing innovative technologies such as variable frequency drives (VFDs) and advanced motor designs, these pumps can operate more efficiently, leading to significant cost savings over time. Reducing energy usage not only lowers operational costs but also contributes to environmental sustainability.

Material Compatibility and Durability

High pressure pumps are exposed to various fluids and conditions, making material compatibility crucial. Advanced high pressure pumps are constructed from durable materials like stainless steel, titanium, and specialty alloys that resist corrosion and wear. Understanding the chemical properties of the fluids being pumped ensures that the materials used will withstand the operational conditions and extend the lifespan of the pump.

Flow Rate Accuracy and Consistency

Flow rate accuracy is essential for maintaining operational integrity. Advanced high pressure pumps come equipped with precise flow measurement instruments that provide real-time data on the fluid being pumped. This level of accuracy helps operators monitor processes, optimize performance, and ensure that systems function without interruptions, thus avoiding costly downtime.

Technology Integration for Enhanced Performance

Modern high pressure pumps are increasingly integrated with smart technology. Features such as IoT connectivity allow for remote monitoring and control, enabling real-time data analysis and predictive maintenance. By utilizing advanced sensors and control systems, operators can gain insights into pump performance, helping to identify potential issues before they escalate into major problems.

Simplicity of Maintenance and Service

Effective maintenance is crucial for the longevity of high pressure pumps. Advanced models are designed for easy access to components, simplifying the maintenance process. Features such as modular designs, self-lubricating systems, and easy-to-replace parts minimize downtime and reduce service costs, allowing operations to run smoothly without extended interruptions.

Applications of High Pressure Pumps

The versatility of high pressure pumps makes them invaluable across various industries. Some notable applications include:

- Manufacturing: Used in processes such as metal fabrication and surface treatment.

- Aerospace: Testing and simulation of aircraft components.

- Food and Beverage: Cleaning and sanitization processes in production lines.

- Mining: Used for slurry transport and mineral processing.

- Pharmaceuticals: Critical in the production of medicines and vaccines.

Choosing the Right High Pressure Pump

Selecting the right high pressure pump requires careful consideration of several factors to ensure optimal performance in your application. Here are some key aspects to evaluate:

- Application Requirements: Assess the specific needs of your process, including the type of fluid, viscosity, and required flow rates.

- Pressure Ratings: Ensure the pump can handle the required pressure levels for your operations.

- Power Source: Consider the availability of power sources and the pump's energy consumption efficiency.

- Size and Configuration: Evaluate the space available for installation and choose a model that fits your layout.

- Manufacturer Reputation: Select pumps from reputable manufacturers known for quality and reliability.

Frequently Asked Questions (FAQs)

1. What is a high pressure pump?

A high pressure pump is a specialized device designed to move fluids at elevated pressures, often over 100 psi, in various industrial applications.

2. How do I know which high pressure pump is suitable for my application?

Evaluate the fluid properties, required flow rates, pressure ratings, and installation space to determine the best pump for your needs.

3. What materials are commonly used in high pressure pump construction?

Common materials include stainless steel, titanium, and various alloys designed to withstand corrosion and high pressure conditions.

4. How can I improve the energy efficiency of my high pressure pump?

Consider using advanced models with variable frequency drives, efficient motors, and regular maintenance to optimize energy consumption.

5. What maintenance practices should I follow for high pressure pumps?

Routine inspection, cleaning, lubrication, and timely replacement of worn components are essential for maintaining pump efficiency and longevity.

Conclusion

Understanding the advanced features of high pressure pumps is essential for making informed decisions that enhance operational efficiency and reliability in various industrial applications. By focusing on energy efficiency, material compatibility, flow rate accuracy, technology integration, and maintenance simplicity, you can select a high pressure pump that meets your specific needs while ensuring long-term performance. Investing in advanced high pressure pumps will not only improve productivity but also contribute to cost savings and sustainability in your operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.