A Comprehensive Guide to Choosing the Right High Pressure Water Pump

Table of Contents

- 1. Introduction to High Pressure Water Pumps

- 2. Understanding High Pressure Water Pumps

- 3. Types of High Pressure Water Pumps

- 4. Key Features to Consider When Choosing a High Pressure Water Pump

- 5. Applications of High Pressure Water Pumps

- 6. How to Select the Right High Pressure Water Pump

- 7. Maintenance Tips for High Pressure Water Pumps

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to High Pressure Water Pumps

High pressure water pumps are vital for various industrial applications, providing an efficient means to transfer water at elevated pressures. Selecting the right pump can greatly affect the operation's efficiency, energy consumption, and overall productivity. In this comprehensive guide, we delve into the essential elements of high pressure water pumps, empowering you to make an informed decision tailored to your specific needs.

2. Understanding High Pressure Water Pumps

High pressure water pumps are designed to generate a higher pressure than standard pumps. They are typically utilized in situations requiring water to be delivered forcefully to specific points, such as irrigation, industrial cleaning, or hydraulic systems. These pumps work by converting mechanical energy into kinetic energy, effectively increasing the water's pressure.

The Importance of Pressure Ratings

When selecting a high pressure water pump, the pressure rating is crucial. The pressure rating, measured in psi (pounds per square inch) or bar, indicates the maximum pressure the pump can handle. A higher rating means the pump can deliver water to greater heights or distances, making it essential to assess the specific requirements of your project.

3. Types of High Pressure Water Pumps

There are several types of high pressure water pumps, each designed for different applications and operational efficiencies. Understanding these types will facilitate a more informed decision.

3.1. Centrifugal High Pressure Pumps

Centrifugal pumps are among the most common types of high pressure water pumps. They work by using a rotating impeller to add velocity to the water, converting kinetic energy into pressure. These pumps are ideal for applications requiring continuous flow and moderate pressure levels.

3.2. Positive Displacement Pumps

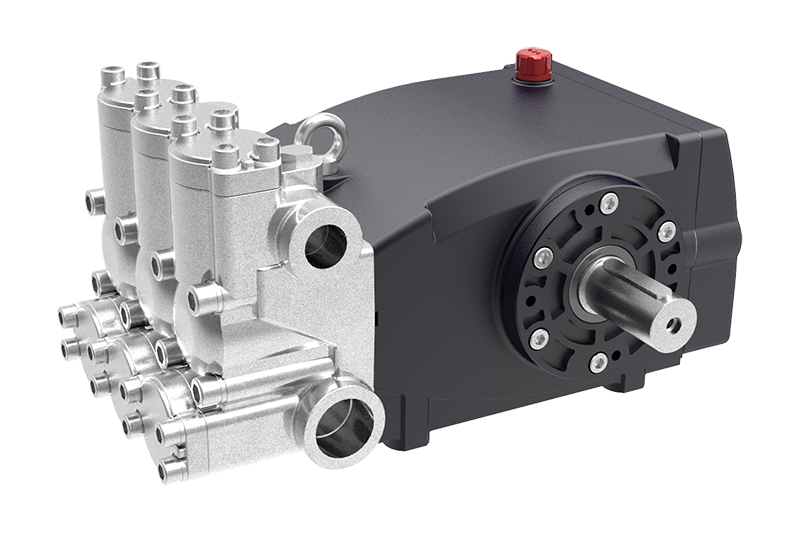

Positive displacement pumps, including gear and diaphragm pumps, function by trapping a fixed amount of fluid and forcing it into the discharge pipe. They are suitable for applications needing higher pressures and consistent flow rates, making them perfect for industrial cleaning tasks.

3.3. Vortex Pumps

Vortex pumps are designed for handling liquids with solid particles without clogging. They create a vortex in the pump body that allows for efficient liquid handling, making them suitable for wastewater management and other applications involving debris.

4. Key Features to Consider When Choosing a High Pressure Water Pump

Selecting the right high pressure water pump involves assessing several key features that can impact performance and suitability for your application.

4.1. Power Source

High pressure pumps can be powered by electricity, gasoline, or diesel. Consider your operational environment and accessibility to power sources when making your choice.

4.2. Flow Rate

Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), is a crucial factor that determines how quickly the pump can move water. Assess your project needs to ensure the chosen pump meets the required flow rate.

4.3. Material Construction

The materials used in the pump construction, such as stainless steel, cast iron, or plastic, affect durability and resistance to corrosion. Select materials based on the fluid's properties and the operating environment.

4.4. Portability

Depending on your application, portability may be a significant consideration. Some high pressure pumps are designed to be portable for job sites, while others are stationary for fixed installations.

4.5. Maintenance Requirements

Understanding the maintenance requirements of your chosen pump can help prolong its lifespan and ensure consistent performance. Some pumps may require more frequent servicing than others, influencing your overall operational costs.

5. Applications of High Pressure Water Pumps

High pressure water pumps find applications across various industries, each requiring specific characteristics to enhance efficiency and productivity.

5.1. Agriculture

In agriculture, high pressure water pumps are utilized for irrigation systems, ensuring crops receive adequate water supply even in remote areas. Their ability to transport water over long distances makes them invaluable in farming operations.

5.2. Industrial Cleaning

High pressure water pumps are essential for industrial cleaning applications, including surface cleaning, equipment maintenance, and waste removal. They provide the force necessary to remove dirt and grime effectively.

5.3. Firefighting

In firefighting applications, high pressure pumps deliver water at high velocities to extinguish fires quickly. These pumps are often integrated into fire truck systems for immediate response capabilities.

5.4. Mining and Construction

In mining and construction, high pressure water pumps are used for dewatering, transporting slurry, and providing water for various processes. Their ability to handle abrasive materials makes them suitable for these demanding environments.

6. How to Select the Right High Pressure Water Pump

Choosing the right high pressure water pump involves a systematic approach to ensure it meets your specific needs. Follow these steps to make an informed decision.

6.1. Evaluate Your Needs

Begin by assessing your specific requirements. Consider factors such as water source, flow rate, pressure needs, and the environment in which the pump will operate.

6.2. Research Available Options

Conduct thorough research on the various pumps available on the market. Compare specifications, features, and reviews to narrow down your options.

6.3. Consult with Experts

If necessary, consult with industry experts or suppliers. Their insights can help guide your decision and provide valuable information about the best options for your needs.

6.4. Test the Pump

If possible, test the pump before making a purchase to ensure it meets your expectations. This step can reveal potential issues that may not be apparent from specifications alone.

7. Maintenance Tips for High Pressure Water Pumps

Proper maintenance is crucial to ensure the longevity and performance of high pressure water pumps. Follow these tips to keep your pump in optimal condition.

7.1. Regular Inspections

Conduct regular inspections of your pump to identify any wear or damage. Check hoses, connections, and seals for leaks or cracks.

7.2. Clean Filters and Strainers

Maintain clean filters and strainers to prevent debris from entering the pump. Clogged filters can cause performance issues and damage the pump.

7.3. Lubrication

Ensure moving parts are adequately lubricated to reduce friction and wear. Consult the manufacturer’s guidelines for lubrication schedules.

7.4. Store Properly

If the pump will not be in use for an extended period, store it in a dry, protected location. Empty the pump of water to prevent freezing or corrosion.

8. Frequently Asked Questions

8.1. What is the difference between centrifugal and positive displacement pumps?

Centrifugal pumps use a rotating impeller to create flow, while positive displacement pumps force water through the system by trapping a fixed volume of liquid.

8.2. How do I determine the right pressure rating for my pump?

Identify the maximum height and distance the water needs to travel. Consult with pump specifications to find a model that meets or exceeds these requirements.

8.3. Can high pressure pumps handle solids?

Some high pressure pumps, like vortex pumps, are designed to handle solids. However, most standard pumps are not suitable for abrasive materials.

8.4. How often should I perform maintenance on my pump?

Maintenance frequency can vary by model and usage. Regular inspections and cleanings should be performed every few months, while specific maintenance tasks may be required more or less frequently based on operating conditions.

8.5. Are high pressure water pumps energy efficient?

Many modern high pressure water pumps are designed for energy efficiency, but it depends on the model and application. Look for energy-efficient models to reduce operational costs.

9. Conclusion

Selecting the right high pressure water pump is essential for optimizing performance and efficiency in various industrial applications. By understanding the different types, key features, and maintenance tips, you can make an informed decision that meets your specific needs. Whether you are in agriculture, cleaning, or construction, the right pump will enhance productivity and reliability in your operations. Always consider your unique requirements and consult with experts to ensure a successful purchase.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.