Why Choose a Fancy High Flow High Pressure Pump for Your Industrial Needs?

Table of Contents

- 1. Introduction to High Flow High Pressure Pumps

- 2. Understanding High Flow High Pressure Pumps

- 3. Advantages of Using High Flow High Pressure Pumps

- 4. Applications of High Flow High Pressure Pumps

- 5. Key Selection Criteria for High Flow High Pressure Pumps

- 6. Maintenance Tips for Longevity

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to High Flow High Pressure Pumps

In the world of industrial operations, **efficient fluid management** is crucial for success. High flow high pressure pumps have emerged as a vital component in various industries, ensuring the effective transfer of fluids under demanding conditions. This article explores the importance of these sophisticated pumps and why they should be a primary consideration for your industrial needs.

2. Understanding High Flow High Pressure Pumps

2.1 Definition and Functionality

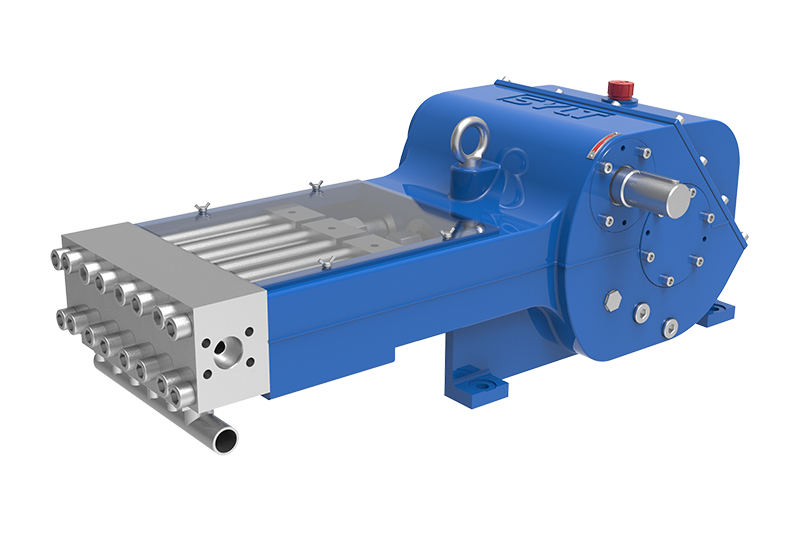

High flow high pressure pumps are specifically designed to handle large volumes of fluid while maintaining significant pressure levels. They are capable of efficiently moving liquids, slurries, and gases, making them indispensable in environments where power and speed are critical. These pumps work on various principles, including centrifugal and positive displacement, depending on the application requirements.

2.2 Types of High Flow High Pressure Pumps

There are several types of high flow high pressure pumps available, each suited for distinct applications:

1. **Centrifugal Pumps**: Ideal for moving large volumes of fluid quickly. They utilize rotational energy to transfer fluids.

2. **Positive Displacement Pumps**: These pumps are designed to move a fixed volume of fluid with each cycle, maintaining high pressure even at low flow rates.

3. **Diaphragm Pumps**: Known for their ability to handle corrosive fluids, these pumps are perfect for industries where fluid composition varies.

3. Advantages of Using High Flow High Pressure Pumps

High flow high pressure pumps offer numerous benefits that make them a preferred choice in various industrial settings.

3.1 Enhanced Efficiency

One of the most significant advantages of high flow high pressure pumps is their efficiency. These pumps can move large quantities of fluid quickly, reducing the time needed for processes such as mixing, spraying, and cleaning. This efficiency can lead to substantial cost savings over time, enhancing overall productivity.

3.2 Superior Performance

High flow high pressure pumps are engineered for **performance**. They deliver consistent pressure and flow rates, ensuring that operations run smoothly without interruptions. Their robust design allows them to handle extreme conditions, making them reliable for various applications.

3.3 Versatility Across Industries

These pumps are incredibly versatile and find applications in numerous industries, including:

- **Chemical Manufacturing**: For moving corrosive substances safely.

- **Oil and Gas**: Essential for transporting crude oil and natural gas.

- **Mining**: Used in slurry transport and dust suppression.

- **Food and Beverage**: Ideal for handling viscous liquids and maintaining hygiene standards.

4. Applications of High Flow High Pressure Pumps

The applications of high flow high pressure pumps are vast. They are instrumental in processes such as:

- **Water Jet Cutting**: Utilizing high-pressure water jets for precision cutting of various materials.

- **Hydraulic Systems**: Powering hydraulic machinery across industrial settings.

- **Pressure Washers**: For effective cleaning in commercial and residential settings, these pumps ensure thorough cleaning with less effort.

- **Spraying Systems**: Essential in agriculture for pesticide and herbicide application.

5. Key Selection Criteria for High Flow High Pressure Pumps

Choosing the right high flow high pressure pump requires careful consideration of several factors.

5.1 Consideration of Flow Rate

Understanding the required flow rate is critical. This specification will determine the type and size of pump necessary for your operations. It’s essential to assess both peak and continuous flow requirements to avoid underperformance.

5.2 Assessing Pressure Requirements

Different applications require different pressure levels. Evaluating the maximum pressure needed for your processes will help in selecting a pump that meets these needs without compromise.

5.3 Material Compatibility

Compatibility with the fluid being pumped is crucial. Ensure that the pump materials can withstand the properties of the fluid, whether it's corrosive, viscous, or abrasive.

6. Maintenance Tips for Longevity

To maximize the lifespan of your high flow high pressure pump, regular maintenance is essential. Here are several key tips:

- **Routine Inspections**: Regularly check for leaks, wear, and unusual noises that might indicate issues.

- **Clean Filters**: Ensure that all filters are clean and functional to maintain optimal performance.

- **Lubrication**: Keep all moving parts well-lubricated according to the manufacturer’s guidelines.

- **Monitor Performance**: Keep track of pressure and flow rates to detect any deviations from normal operation.

7. Frequently Asked Questions

What is the primary function of a high flow high pressure pump?

The primary function is to efficiently transfer fluids at high flow rates and pressures, making them suitable for various industrial applications.

How do I know which type of pump is best for my needs?

Assess your specific requirements, including flow rate, pressure, and the type of fluid you'll be handling to determine the best pump type.

What kind of maintenance do high flow high pressure pumps require?

Regular inspections, cleaning of filters, lubrication of moving parts, and monitoring of performance metrics are crucial for longevity.

Can high flow high pressure pumps handle corrosive fluids?

Yes, many high flow high pressure pumps are designed with materials that can withstand corrosive substances, making them ideal for chemical applications.

What industries benefit most from high flow high pressure pumps?

Industries such as chemical manufacturing, oil and gas, mining, and food and beverage significantly benefit from the use of these pumps.

8. Conclusion

In conclusion, selecting a **high flow high pressure pump** for your industrial needs is a strategic decision that can greatly influence your operational efficiency and overall productivity. With their unparalleled performance, versatility, and ability to handle demanding conditions, these pumps stand as a cornerstone in various industrial applications. By understanding the key features, advantages, and maintenance practices associated with high flow high pressure pumps, you position your operations for success and longevity. Investing in the right pump will not only meet your current needs but also adapt to future challenges, ensuring your business remains competitive in a rapidly evolving industrial landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.