Why Classy Industrial High Pressure Pumps Are Essential for Your Business

Table of Contents

- Introduction to High Pressure Pumps

- The Importance of High Pressure Pumps in Industry

- Benefits of Classy Industrial High Pressure Pumps

- Applications of High Pressure Pumps

- Key Features of Classy High Pressure Pumps

- How to Select the Right High Pressure Pump for Your Needs

- Maintenance Tips for High Pressure Pumps

- Why Investing in High Quality Pumps Matters

- Conclusion

- Frequently Asked Questions

Introduction to High Pressure Pumps

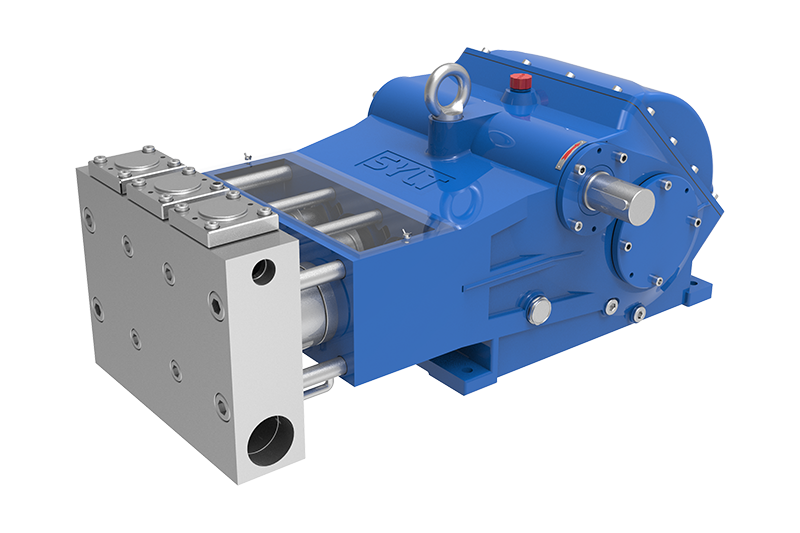

High pressure pumps play a pivotal role in various industrial applications, providing the necessary power to move fluids at exceptional pressures. These pumps are designed to handle demanding conditions and are critical for ensuring operational efficiency. In an era where competition is fierce, having reliable equipment like classy high pressure pumps can be the difference between success and failure.

The Importance of High Pressure Pumps in Industry

The significance of high pressure pumps cannot be overstated. These pumps are engineered to provide superior performance in environments that require high flow rates and pressures. Industries such as manufacturing, chemical processing, and food and beverage heavily rely on these pumps to maintain smooth operations.

The need for high pressure pumps arises from their ability to facilitate various processes, including fluid transfer, spray cleaning, and hydraulic applications. By investing in quality pumps, businesses can ensure that they meet industry standards and customer demands without compromising on reliability.

Benefits of Classy Industrial High Pressure Pumps

Classy industrial high pressure pumps come equipped with several advantages that enhance overall operational efficiency. Here are some of the key benefits:

1. Enhanced Performance

High pressure pumps are designed for optimal fluid delivery, ensuring that business operations run smoothly. Their ability to maintain consistent pressure and flow rates makes them ideal for demanding environments.

2. Durability and Longevity

Quality pumps are built to withstand harsh conditions, offering long-lasting performance. Investing in classy high pressure pumps means fewer replacements and repairs, ultimately saving businesses money.

3. Versatility

These pumps can be utilized across various applications, making them a versatile choice for different industries. Whether it's handling water, chemicals, or viscous fluids, high pressure pumps adapt to diverse needs.

4. Improved Safety

Safety is paramount in industrial settings. High pressure pumps reduce the risk of leaks and spills, ensuring a safer working environment for employees.

5. Cost Efficiency

While the initial investment may seem significant, classy high pressure pumps contribute to long-term savings through energy efficiency and reduced operational costs. They utilize advanced technology to minimize energy consumption while maximizing output.

Applications of High Pressure Pumps

Classy high pressure pumps find applications across a multitude of sectors. Understanding these applications is crucial for businesses looking to optimize their operations.

Manufacturing Sector

In the manufacturing sector, high pressure pumps are utilized for tasks such as injection molding, material transfer, and surface cleaning. Their ability to deliver consistent pressure ensures high-quality output while reducing operational downtime.

Food and Beverage Industry

The food and beverage industry relies on high pressure pumps for processes like pasteurization, bottling, and cleaning. These pumps ensure that products meet safety regulations while maintaining quality.

Chemical Processing

High pressure pumps are vital in chemical processing applications, handling corrosive and viscous fluids. Their robust design allows for safe and efficient transfer of chemicals, enhancing productivity.

Water Treatment

In water treatment facilities, high pressure pumps are used for filtration, reverse osmosis, and distribution. They play a crucial role in ensuring clean and safe water supply to communities.

Key Features of Classy High Pressure Pumps

When selecting high pressure pumps, it's essential to understand the features that distinguish classy models from standard ones. Here are some key features to consider:

1. High Efficiency

Classy high pressure pumps are engineered for high efficiency, minimizing energy consumption while maximizing output. This is particularly important in large-scale operations where energy costs can significantly impact the bottom line.

2. Advanced Materials

Quality pumps are constructed from durable materials that resist wear and corrosion. This ensures a longer lifespan and reduces maintenance requirements.

3. Customizable Options

Many high pressure pumps offer customizable options, allowing businesses to tailor specifications to their unique needs. This flexibility can enhance performance in specialized applications.

4. User-Friendly Design

Classy pumps are designed with the user in mind, featuring intuitive interfaces and easy maintenance access. This reduces training time and enhances operational efficiency.

5. Comprehensive Warranty

Investing in reputable brands often comes with the assurance of a comprehensive warranty. This provides peace of mind that the investment is protected against unforeseen failures.

How to Select the Right High Pressure Pump for Your Needs

Choosing the right high pressure pump is crucial for optimizing your business operations. Here are some steps to ensure you make the best selection:

1. Assess Your Requirements

Identify the specific needs of your application, including the type of fluid, required flow rate, and pressure. Understanding these parameters is essential for making an informed decision.

2. Consult with Experts

Engaging with pump specialists or engineers can provide valuable insights into suitable options. They can recommend products that meet your needs while considering factors like cost and efficiency.

3. Evaluate Performance Metrics

Review performance metrics such as flow rate, pressure capabilities, and energy efficiency. This helps ensure that the pump can handle your operational demands.

4. Consider Maintenance Needs

Some pumps require more maintenance than others. Evaluate the maintenance needs versus your team’s capacity to manage these requirements effectively.

5. Compare Manufacturer Reputation

Research manufacturers and their reputations in the industry. Reliable brands often provide better support and warranty options, ensuring you have a trustworthy partner for your equipment needs.

Maintenance Tips for High Pressure Pumps

Regular maintenance is essential for ensuring the longevity and efficiency of high pressure pumps. Here are some tips to keep your pumps in optimal condition:

1. Regular Inspections

Conduct routine inspections to identify wear and tear. Look for signs of leaks, unusual noise, and changes in performance.

2. Change Filters and Seals

Regularly replace filters and seals to prevent contaminants from damaging pump components.

3. Lubrication

Ensure that moving parts are properly lubricated to reduce friction and wear. This is crucial for maintaining efficiency.

4. Monitor Performance

Keep track of performance metrics to spot any deviations. Early detection of issues can prevent costly repairs and downtime.

5. Professional Servicing

Schedule professional servicing at regular intervals to address any complex maintenance needs. Technicians can provide insights that enhance pump longevity.

Why Investing in High Quality Pumps Matters

Investing in classy industrial high pressure pumps is not just about purchasing equipment; it’s about securing the future of your business. High-quality pumps lead to better performance, reduced costs, and improved safety.

The initial investment may be higher than lower-quality alternatives, but the long-term benefits far outweigh these costs. By choosing reliable pumps, businesses can improve productivity and ensure that they can meet customer demands consistently.

Conclusion

Classy industrial high pressure pumps are not just a piece of equipment; they are an essential component of successful business operations across various industries. Their reliability, efficiency, and versatility make them indispensable in today’s competitive landscape. By investing in high-quality pumps and following proper maintenance practices, businesses can significantly enhance their operational capabilities while ensuring safety and compliance with industry standards.

Frequently Asked Questions

1. What types of fluids can high pressure pumps handle?

High pressure pumps can handle a variety of fluids, including water, chemicals, and viscous fluids, depending on their design and materials.

2. How do I know if I need a high pressure pump?

If your application requires fluid transfer at high flow rates or pressures, a high pressure pump may be necessary to meet those demands.

3. What maintenance is required for high pressure pumps?

Regular inspections, filter changes, lubrication, and professional servicing are recommended to maintain the efficiency and longevity of high pressure pumps.

4. Are high pressure pumps energy efficient?

Classy high pressure pumps are often designed with energy efficiency in mind, helping to reduce operational costs while maintaining performance.

5. What should I consider when selecting a high pressure pump?

Consider your specific application requirements, manufacturer reputation, performance metrics, and maintenance needs when selecting a high pressure pump.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.