How to Choose the Best High Pressure Plunger Pump for Your Business

Table of Contents

- Understanding High Pressure Plunger Pumps

- Common Applications of High Pressure Plunger Pumps

- Key Specifications to Consider

- Choosing the Right Capacity for Your Needs

- Materials and Design: Finding the Right Fit

- Evaluating Performance and Efficiency

- Maintenance and Support Considerations

- Weighing Cost Against Value

- Frequently Asked Questions

Understanding High Pressure Plunger Pumps

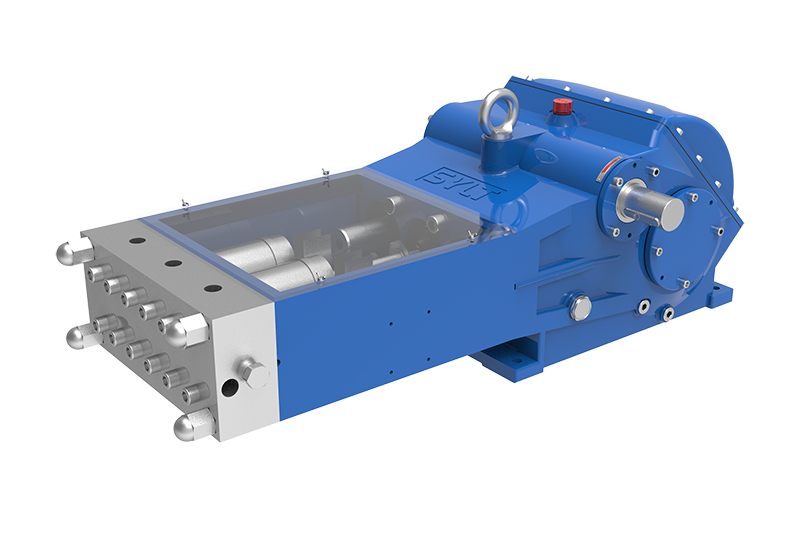

High pressure plunger pumps are precision-engineered devices that utilize a reciprocating plunger to move fluids at high pressures. Known for their reliability and efficiency, these pumps are essential in various industrial applications, ensuring the smooth operation of processes that require precise liquid transfer. Understanding the mechanics behind these pumps is crucial for making an informed purchase decision.

How Plunger Pumps Work

The fundamental operation of a plunger pump involves a cylinder, a plunger, and inlet and outlet valves. As the plunger moves back and forth, it creates a vacuum that draws fluid into the cylinder. When the plunger moves forward, the fluid is forced out through the outlet valve, generating high pressure. This simple yet effective mechanism allows for consistent and powerful fluid transfer.

Advantages of High Pressure Plunger Pumps

High pressure plunger pumps offer numerous advantages, including:

- **High Efficiency**: They provide maximum flow rates with minimal energy consumption.

- **Versatility**: Suitable for various fluids, including corrosive and viscous liquids.

- **Durability**: Built to withstand harsh operating conditions, ensuring a long service life.

- **Precision**: Capable of delivering precise flow rates, critical for applications requiring accuracy.

Common Applications of High Pressure Plunger Pumps

High pressure plunger pumps find applications across multiple industries. Understanding where these pumps are most commonly used can help you determine their relevance to your business needs.

Industrial Cleaning

In industries where cleanliness is paramount, such as food processing and pharmaceuticals, high pressure plunger pumps are used for cleaning equipment and surfaces. Their ability to generate high-pressure streams of water or cleaning solutions ensures thorough sanitation.

Agriculture

In agricultural applications, these pumps are utilized for irrigation and pesticide spraying, delivering chemicals at precise rates to optimize crop yields.

Manufacturing

In manufacturing, especially in sectors such as automotive and aerospace, high pressure plunger pumps are used for testing components, ensuring they withstand high-pressure conditions.

Oil and Gas

The oil and gas industry relies on high pressure plunger pumps for various tasks, including fluid transfer and pressure testing of pipelines and equipment.

Key Specifications to Consider

Choosing the best high pressure plunger pump involves evaluating several key specifications that directly impact performance and compatibility with your operations.

Flow Rate

The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move within a given timeframe. It is essential to select a pump with a flow rate that aligns with your operational requirements.

Pressure Rating

The pressure rating, usually expressed in PSI (pounds per square inch) or bar, indicates the maximum pressure the pump can generate. Your application will dictate the necessary pressure rating. For example, industrial cleaning applications may require higher pressures than agricultural uses.

Power Requirements

Understanding the power requirements is crucial for ensuring compatibility with existing equipment. Most high pressure plunger pumps operate on electricity, but there are also diesel and hydraulic options available.

Size and Weight

Consider the physical size and weight of the pump, especially if it needs to be transported or installed in a restricted space. Ensure that your facility can accommodate the pump's dimensions.

Choosing the Right Capacity for Your Needs

Selecting the right capacity for your high pressure plunger pump is vital for optimal performance. Factors to consider include:

Application Requirements

Assess the specific requirements of your application. If you need the pump for heavy-duty tasks, prioritize pumps with higher capacities. For lighter tasks, a smaller capacity may suffice.

Future Growth

Anticipate future needs. If you plan to expand your operations, consider investing in a pump with a higher capacity to avoid the need for replacement soon.

Materials and Design: Finding the Right Fit

The materials used in the construction of high pressure plunger pumps significantly affect their performance and longevity.

Corrosion Resistance

If your applications involve corrosive fluids, look for pumps constructed from materials such as stainless steel or specialized alloys to prevent degradation.

Ease of Maintenance

Consider the design of the pump. A well-designed pump will allow for easy access to components for maintenance and repair, reducing downtime and operational costs.

Evaluating Performance and Efficiency

To ensure you select a high pressure plunger pump that meets your business needs, evaluating performance and efficiency is crucial.

Energy Efficiency

Look for pumps with high energy efficiency ratings, as these will save operational costs in the long run. Manufacturers often provide performance curves that illustrate energy consumption at various flow rates and pressures.

Reliability Ratings

Research the reliability ratings and customer reviews for different pump models. Reliable pumps reduce the risk of breakdowns and costly repairs.

Maintenance and Support Considerations

Proper maintenance is essential for ensuring the longevity of your high pressure plunger pump. Consider the following:

Maintenance Requirements

Understand the maintenance needs of the pump model you’re considering. Some pumps require regular servicing, while others are designed for minimal upkeep.

Manufacturer Support

Evaluate the level of support provided by the manufacturer. Reliable manufacturers offer extensive customer support and readily available replacement parts.

Weighing Cost Against Value

When choosing a high pressure plunger pump, it’s essential to balance cost with the value it offers. A lower-priced pump may save you money initially but could lead to higher maintenance and replacement costs down the line.

Initial Investment

Consider the upfront cost of the pump, including installation expenses. Compare prices across different manufacturers while also considering the specifications and features offered.

Long-Term Costs

Factor in long-term costs such as maintenance, energy consumption, and potential downtime. A pump that requires frequent repairs could end up being more expensive than a higher-quality model.

Frequently Asked Questions

What is the lifespan of a high pressure plunger pump?

The lifespan can vary significantly based on usage and maintenance, but with proper care, they can last anywhere from 5 to 20 years.

Can high pressure plunger pumps handle corrosive fluids?

Yes, but it’s crucial to select a pump constructed from corrosion-resistant materials to avoid damage.

How often should I perform maintenance on my pump?

Maintenance frequency depends on the pump's usage. Generally, routine checks should be conducted monthly, with more detailed inspections quarterly or biannually.

What is the difference between a plunger pump and a diaphragm pump?

Plunger pumps utilize a plunger mechanism for fluid movement, while diaphragm pumps use a diaphragm to create a vacuum. Plunger pumps are typically better for high-pressure applications.

Are there any safety considerations when using high pressure pumps?

Yes, always follow safety guidelines, including wearing appropriate protective gear and ensuring that the pump is securely mounted to prevent accidents.

Conclusion

Choosing the best high pressure plunger pump for your business is a critical decision that can significantly impact your operational efficiency and costs. By understanding the mechanics, applications, specifications, and maintenance needs of these pumps, you can make an informed choice that meets your specific needs. Remember to weigh the initial investment against long-term value, ensuring that you select a high-quality, reliable pump that will serve your business effectively for years to come. By following this guide, we believe you will confidently select the right high pressure plunger pump that enhances your business operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.