Transform Your Cleaning Routine with a High Pressure Cleaning Machine for Industrial Use

In today’s fast-paced industrial environment, efficiency and effectiveness are paramount. Traditional cleaning methods often fall short when it comes to tackling stubborn dirt, grease, and grime. This is where a high pressure cleaning machine comes into play. These powerful tools are designed to revolutionize your cleaning routine, making it faster, easier, and more efficient. In this article, we will explore the various aspects of high-pressure cleaning machines, their benefits for industrial use, and how to choose the right one for your specific needs.

Table of Contents

- What is High Pressure Cleaning?

- Benefits of High Pressure Cleaning in Industrial Settings

- How Does a High Pressure Cleaning Machine Work?

- Types of High Pressure Cleaning Machines

- Choosing the Right High Pressure Cleaning Machine

- Applications of High Pressure Cleaning Machines in Industrial Cleaning

- Maintenance and Safety Tips for High Pressure Cleaning

- Frequently Asked Questions

- Conclusion

What is High Pressure Cleaning?

High pressure cleaning is a method that employs a powerful stream of water at high pressure to remove dirt, grime, grease, and other contaminants from various surfaces. This cleaning technique is particularly effective in industrial environments, where traditional cleaning methods may not suffice. The high-pressure water jet eliminates the need for harsh chemicals, making it an eco-friendly option.

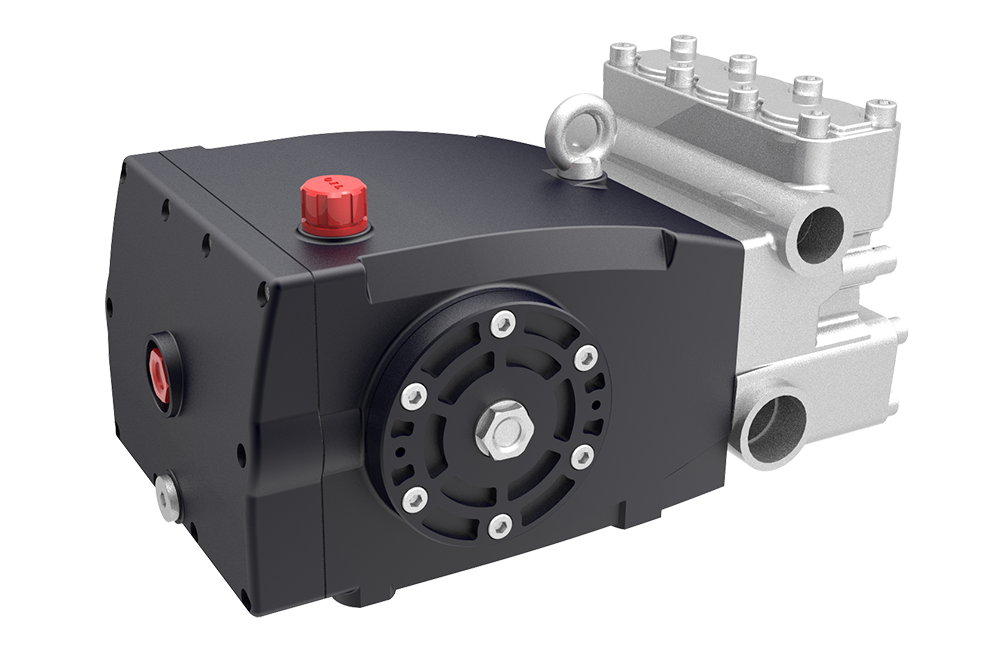

Understanding the Mechanics of High Pressure Cleaning

A high pressure cleaning machine typically consists of a motor, a pump, and a spray nozzle. The motor powers the pump, which increases the water pressure and propels the water through the nozzle at high speed. This process creates a focused stream of water that can reach and clean hard-to-access areas effectively.

Benefits of High Pressure Cleaning in Industrial Settings

Adopting high pressure cleaning machines in industrial operations offers numerous advantages, enhancing both efficiency and effectiveness.

Enhanced Cleaning Efficiency

High pressure cleaning machines can clean surfaces much faster than traditional methods. By utilizing concentrated water jets, these machines can cover large areas in a fraction of the time it would take to scrub manually.

Cost-Effectiveness

Although high pressure cleaning machines may require an initial investment, they can save money in the long run. Reduced labor costs and the decreased need for chemical detergents contribute to overall cost savings.

Versatile Applications

These machines are incredibly versatile, capable of cleaning a wide range of surfaces, including concrete, metal, and even delicate materials when used with the right settings. They can be used for various tasks, from cleaning machinery to maintaining facilities.

Environmentally Friendly Cleaning

High pressure cleaning machines often require less water and fewer chemicals than traditional methods, making them a more sustainable option. This is particularly important in industries that prioritize environmental responsibility.

How Does a High Pressure Cleaning Machine Work?

Understanding the inner workings of a high pressure cleaning machine can help you appreciate its effectiveness. Here’s a breakdown of the process:

Components of a High Pressure Cleaning Machine

- Motor: Powers the pump.

- Pump: Increases water pressure.

- Nozzle: Directs and controls the flow of water.

- Hose: Connects the machine to the water source.

- Water Tank: Stores water for cleaning.

Operating Principles

The motor drives the pump, which pressurizes the water. When the trigger on the nozzle is pulled, the pressurized water is released, creating a high-velocity jet that effectively removes dirt and contaminants from surfaces. The pressure can typically be adjusted, allowing for customized cleaning based on the surface material and type of grime.

Types of High Pressure Cleaning Machines

Choosing the right type of high pressure cleaning machine for your industrial needs is crucial. Below are the main types available:

Electric High Pressure Cleaners

These machines are ideal for light to medium-duty cleaning tasks. They are quieter, more compact, and easier to maintain, making them suitable for indoor use and smaller outdoor areas.

Gas-Powered High Pressure Cleaners

For more demanding cleaning tasks, gas-powered machines offer higher pressure and flow rates. They are portable and suitable for outdoor applications where electricity may not be available.

Hot Water High Pressure Cleaners

These machines utilize hot water to enhance cleaning power, making them excellent for removing grease and oil. The combination of high pressure and heat significantly increases cleaning efficiency.

Choosing the Right High Pressure Cleaning Machine

When selecting a high pressure cleaning machine, consider the following factors:

Pressure Ratings

The pressure rating, measured in PSI (pounds per square inch), indicates the force of the water jet. Depending on your cleaning needs, you may require a machine with higher or lower pressure capabilities.

Flow Rate

Flow rate, measured in GPM (gallons per minute), affects how quickly you can clean an area. A higher flow rate means more water is used, which can enhance cleaning efficiency.

Portability

Consider whether you need a stationary or portable machine. Portable machines are beneficial for various locations, while stationary units may better serve large facilities.

Accessories and Attachments

Look for machines that come with various nozzles and accessories to enhance their versatility, allowing you to tackle different cleaning tasks effectively.

Applications of High Pressure Cleaning Machines in Industrial Cleaning

High pressure cleaning machines have a wide range of applications in various industrial sectors:

Manufacturing Facilities

In manufacturing, these machines are used to maintain machinery, remove waste, and ensure a clean working environment, contributing to operational efficiency.

Construction Sites

Construction sites benefit from high pressure cleaning for removing dirt, dust, and construction debris from equipment and surfaces, improving safety and productivity.

Food Processing Plants

In the food industry, sanitation is critical. High pressure cleaners can effectively remove grease and contaminants from food processing machinery, ensuring compliance with safety regulations.

Maintenance and Safety Tips for High Pressure Cleaning

To ensure your high pressure cleaning machine operates optimally, regular maintenance and safety precautions are essential:

Regular Maintenance Practices

- Check and clean filters regularly.

- Inspect hoses and nozzles for wear and tear.

- Lubricate moving parts as per the manufacturer’s guidelines.

- Store the machine properly when not in use.

Safety Precautions

Safety is paramount when using high pressure cleaning machines. Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. Be aware of your surroundings and ensure that bystanders are at a safe distance during operation.

Frequently Asked Questions

1. How much pressure do I need for industrial cleaning?

The required pressure varies based on the cleaning task. For general cleaning, 1500-3000 PSI is sufficient, while heavier tasks may require higher pressure.

2. Can I use a high pressure cleaning machine indoors?

Electric high pressure cleaners are suitable for indoor use due to lower noise levels and no emissions. Ensure adequate ventilation when using gas-powered machines indoors.

3. How often should I perform maintenance on my machine?

Regular maintenance should be performed every few months or after heavy use, depending on the manufacturer’s recommendations.

4. Are there any surfaces that should not be cleaned with a high pressure cleaning machine?

Yes, delicate surfaces such as certain types of wood, shingles, or unsealed surfaces can be damaged by high pressure. Always check the manufacturer’s guidelines.

5. What accessories do I need for my high pressure cleaning machine?

Common accessories include various nozzles, surface cleaners, extension wands, and brushes, which can enhance cleaning efficiency and versatility.

Conclusion

Investing in a high pressure cleaning machine can significantly transform your cleaning routine in industrial settings. With their efficiency, versatility, and eco-friendly benefits, these machines are essential for maintaining cleanliness and safety in any industrial environment. By understanding how they work and the factors to consider when choosing one, you can make an informed decision that enhances your operations. Embrace the power of high pressure cleaning and experience the difference it can make in your industrial cleaning tasks.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.