Exploring the Benefits of Using Advanced High Pressure Pumps in Manufacturing

Table of Contents

- 1. Introduction to High Pressure Pumps

- 2. What Are High Pressure Pumps?

- 3. Applications of High Pressure Pumps in Manufacturing

- 4. Advantages of Using Advanced High Pressure Pumps

- 5. Types of Advanced High Pressure Pumps

- 6. Maintenance of High Pressure Pumps

- 7. The Future of High Pressure Pump Technology

- 8. FAQs

- 9. Conclusion

1. Introduction to High Pressure Pumps

In today's highly competitive manufacturing landscape, efficiency and productivity are paramount. Advanced high pressure pumps have emerged as vital components in various industrial sectors, providing significant advantages in fluid handling processes. Understanding the role and benefits of these pumps can greatly enhance a company's operations.

2. What Are High Pressure Pumps?

High pressure pumps are mechanical devices designed to move liquids or gases at elevated pressures. These pumps are essential for several applications, including water treatment, oil and gas extraction, and chemical processing. By generating pressure levels that can exceed thousands of psi (pounds per square inch), they facilitate the movement of fluids through systems that require precise control and high efficiency.

3. Applications of High Pressure Pumps in Manufacturing

The versatility of high pressure pumps allows them to be integrated into various manufacturing processes. Common applications include:

- **Cleaning and Surface Preparation**: High pressure pumps are often used in industrial cleaning systems to remove contaminants from surfaces, ensuring better adhesion for coatings and finishes.

- **Injection Molding**: In manufacturing plastics, these pumps inject materials into molds under high pressure, producing intricate designs with excellent dimensional accuracy.

- **Metal Surface Treatment**: High pressure water jetting is utilized for cutting and cleaning metals, providing precision and minimizing waste.

- **Food Processing**: In this sector, high pressure pumps are crucial for processes such as pasteurization and homogenization, ensuring product safety and consistency.

4. Advantages of Using Advanced High Pressure Pumps

Integrating advanced high pressure pumps into manufacturing processes offers numerous benefits.

4.1 Enhanced Efficiency

One of the primary advantages of high pressure pumps is their ability to improve operational efficiency. By delivering fluids at high pressures, these pumps reduce the time required for various processes. For example, in cleaning applications, high pressure systems can eliminate the need for harsh chemicals and lengthy scrubbing, resulting in quicker turnaround times.

4.2 Cost Savings

While the initial investment in advanced high pressure pumps may be significant, the long-term savings can be substantial. Enhanced efficiency translates to lower energy consumption and reduced labor costs. Additionally, these pumps often require less maintenance than traditional systems, minimizing downtime and associated costs.

4.3 Improved Product Quality

Advanced high pressure pumps contribute to superior product quality. By enabling precise control over fluid dynamics, manufacturers can achieve consistent product specifications and reduce defects. In industries where quality is critical, such as pharmaceuticals and food processing, using high pressure pumps can be a game changer.

4.4 Environmental Impact

The use of high pressure pumps can also result in a reduced environmental footprint. Their efficiency often allows for lower energy usage and decreased water consumption. Moreover, high pressure cleaning systems can minimize the need for chemical cleaners, aligning with eco-friendly manufacturing practices.

5. Types of Advanced High Pressure Pumps

There are several types of advanced high pressure pumps, each designed for specific applications and fluid types.

5.1 Diaphragm Pumps

Diaphragm pumps are ideal for handling corrosive and viscous fluids. They operate by isolating the fluid from the mechanical components, thereby preventing contamination and wear. This type of pump is often used in chemical processing and wastewater treatment.

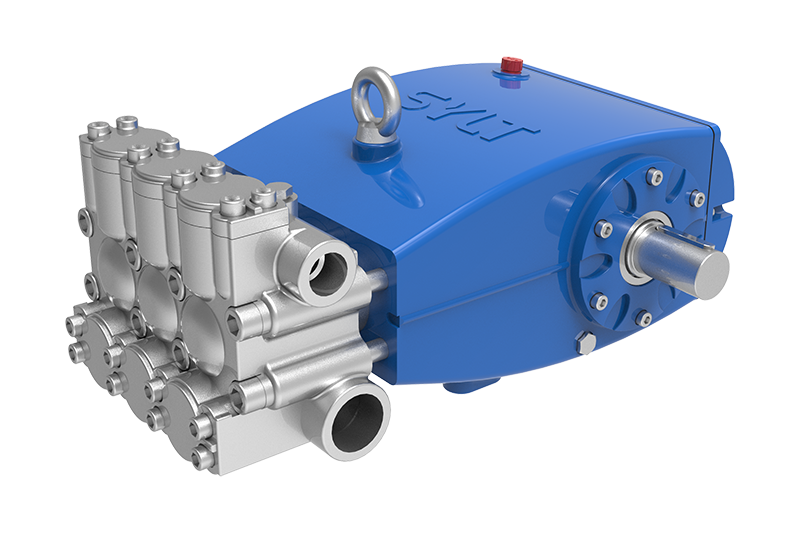

5.2 Plunger Pumps

Plunger pumps are known for their ability to deliver high pressures and flow rates. They utilize a reciprocating plunger to create pressure, making them suitable for applications such as oil and gas extraction and high-pressure cleaning.

5.3 Gear Pumps

Gear pumps are efficient for moving viscous fluids and are commonly used in manufacturing industries that handle oils and lubricants. Their design allows for continuous flow and precise metering.

6. Maintenance of High Pressure Pumps

Proper maintenance of high pressure pumps is essential to ensure optimal performance and longevity. Regular inspections, lubrication, and timely replacement of worn components are critical practices. Manufacturers should implement a proactive maintenance schedule to prevent breakdowns and costly repairs.

7. The Future of High Pressure Pump Technology

As technology advances, high pressure pumps are expected to become even more efficient and versatile. Innovations such as smart monitoring systems, which use IoT technology to provide real-time data on pump performance, will enhance operational efficiency and maintenance strategies. Moreover, the growing emphasis on sustainability will drive the development of more environmentally friendly pump technologies.

8. FAQs

What industries commonly use high pressure pumps?

High pressure pumps are utilized across various industries, including oil and gas, food processing, pharmaceuticals, and manufacturing.

How do high pressure pumps differ from low pressure pumps?

High pressure pumps are designed to generate and sustain significantly higher psi levels than low pressure pumps, making them suitable for applications that require precise fluid control and high efficiency.

What factors should be considered when selecting a high pressure pump?

Considerations include the type of fluid being pumped, the required flow rate, pressure levels, and the specific application requirements.

How can I ensure the longevity of my high pressure pump?

Regular maintenance, including inspections, lubrication, and prompt replacement of worn parts, is crucial for ensuring the longevity of high pressure pumps.

Are there environmentally friendly options available in high pressure pumps?

Yes, advancements in high pressure pump technology have led to the development of more efficient models that consume less energy and reduce waste, aligning with eco-friendly practices.

9. Conclusion

The integration of advanced high pressure pumps in manufacturing processes provides a multitude of benefits, including enhanced efficiency, cost savings, improved product quality, and reduced environmental impact. As industries continue to evolve, the demand for high pressure pumps will likely grow, paving the way for innovative technologies that further enhance their capabilities. Investing in the right pump technology is crucial for manufacturers looking to gain a competitive edge in today's dynamic market. Embracing these advancements can lead to significant operational improvements and a robust return on investment.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.