Exploring the Mechanisms Behind Advanced High Pressure Plunger Pumps

Table of Contents

- 1. Introduction to High Pressure Plunger Pumps

- 2. Mechanical Design of Plunger Pumps

- 3. Operating Principles of High Pressure Plunger Pumps

- 4. Key Components of Advanced High Pressure Plunger Pumps

- 5. Applications of High Pressure Plunger Pumps

- 6. Benefits of Using High Pressure Plunger Pumps

- 7. Maintenance Practices for Longevity

- 8. Common Issues and Troubleshooting

- 9. Conclusion

- 10. Frequently Asked Questions

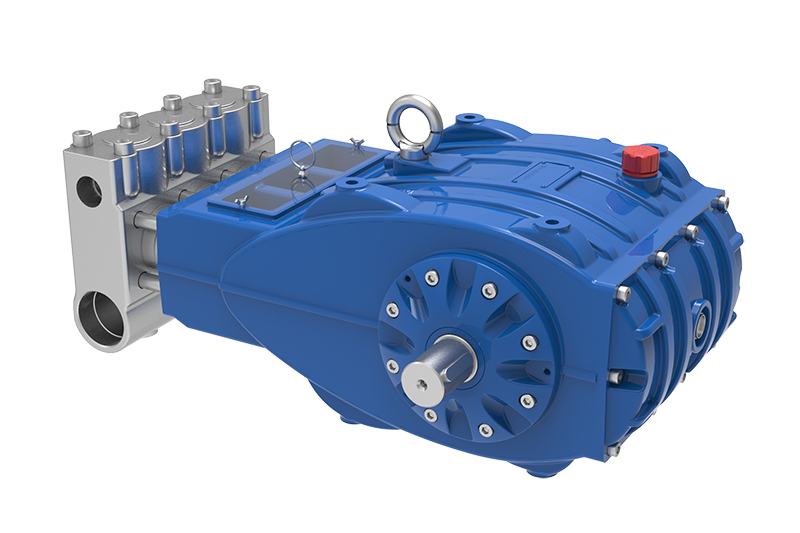

1. Introduction to High Pressure Plunger Pumps

High pressure plunger pumps are critical machinery components widely used in various sectors, including manufacturing, oil and gas, and chemical processing. These pumps are designed to handle demanding applications requiring precise fluid delivery at elevated pressures. Understanding the mechanisms behind these pumps enhances operational efficiency and reliability, ensuring optimal performance in industrial applications.

2. Mechanical Design of Plunger Pumps

The mechanical design of high pressure plunger pumps is a testament to engineering innovation. These pumps feature a unique configuration that maximizes efficiency while minimizing wear and tear.

2.1 Basic Structure

At their core, plunger pumps consist of a cylinder, plunger, and a set of valves. The cylinder houses the plunger, which moves back and forth to create pressure. Inlet and outlet valves control the flow of fluid, ensuring a smooth operation.

2.2 Materials Used

The materials chosen for constructing high pressure plunger pumps are crucial. Manufacturers typically utilize stainless steel or high-strength alloys to withstand the immense pressures involved. These materials are resistant to corrosion and ensure durability.

3. Operating Principles of High Pressure Plunger Pumps

Understanding the operating principles of high pressure plunger pumps involves grasping how fluid dynamics and mechanical motion contribute to their functionality.

3.1 Stroke Cycle

The operation begins with the plunger retracting, creating a vacuum that allows fluid to enter the pump through the inlet valve. As the plunger advances, it compresses the fluid, pushing it through the outlet valve under high pressure. This cycle repeats continuously, enabling the pump to deliver fluid efficiently.

3.2 Pressure Regulation

Pressure regulation is vital in high pressure applications. These pumps often incorporate pressure relief valves to prevent excessive pressure buildup, ensuring safety and preventing damage to the system.

4. Key Components of Advanced High Pressure Plunger Pumps

A detailed understanding of the key components is essential for anyone involved in the operation or maintenance of high pressure plunger pumps.

4.1 Plunger

The plunger is a critical component responsible for generating pressure. Its design—typically cylindrical—allows for effective fluid displacement. The surface finish of the plunger plays a significant role in minimizing friction and enhancing efficiency.

4.2 Valves

Valves are crucial for controlling fluid flow. The design of the inlet and outlet valves often dictates the pump's efficiency. Many advanced models utilize check valves that ensure one-way flow, preventing backflow.

4.3 Cylinder

The cylinder encases the plunger and is designed to withstand high pressures. The surface integrity of the cylinder is vital for maintaining operational efficiency and preventing leakage.

5. Applications of High Pressure Plunger Pumps

High pressure plunger pumps find applications across various industries due to their reliability and efficiency.

5.1 Oil and Gas Industry

In the oil and gas sector, these pumps are utilized for transferring crude oil and other high-viscosity fluids. Their ability to maintain pressure over long distances makes them indispensable.

5.2 Water Jet Cutting

High pressure plunger pumps are integral in water jet cutting technologies. Their capability to generate extreme pressure enables the cutting of hard materials with precision.

5.3 Chemical Processing

In chemical processing, these pumps are used for transporting corrosive fluids safely. Their robust design allows for handling aggressive chemicals without compromising integrity.

6. Benefits of Using High Pressure Plunger Pumps

The advantages of high pressure plunger pumps are notable, contributing to their widespread adoption in various sectors.

6.1 Efficiency

These pumps provide a high flow rate even at elevated pressures, making them efficient choices for demanding applications. Their design minimizes energy loss, contributing to overall operational efficiency.

6.2 Durability

Constructed from high-quality materials, high pressure plunger pumps are built to last. Their resistance to wear and corrosion translates to reduced maintenance costs over time.

6.3 Precision

Plunger pumps offer precise fluid delivery, crucial for industries that require accuracy in their processes. This precision contributes to higher quality outputs and less material waste.

7. Maintenance Practices for Longevity

Proper maintenance is essential to ensure the longevity and reliability of high pressure plunger pumps.

7.1 Regular Inspections

Conducting regular inspections helps identify wear and tear before they escalate into significant issues. Checking seals, valves, and the plunger's condition ensures optimal performance.

7.2 Lubrication

Adequate lubrication of moving parts is vital for reducing friction and wear. Employing the right type of lubricant can enhance the pump's efficiency and lifespan.

7.3 Cleaning

Regular cleaning of the pump prevents buildup of contaminants that could affect performance. Ensuring all components are free from debris is crucial for smooth operation.

8. Common Issues and Troubleshooting

Understanding common issues and their solutions can save time and costs associated with pump failures.

8.1 Low Pressure Output

If a pump is not generating the expected pressure, it may indicate a valve malfunction or a worn plunger. Inspecting and replacing these components can restore performance.

8.2 Leakage

Leakage often results from worn seals or damaged components. Identifying the source of the leak and replacing the faulty parts is essential to prevent fluid loss.

8.3 Unusual Noises

Strange noises during operation may signal mechanical issues. Investigating the cause—whether it be loose components or improper lubrication—is vital for maintaining pump integrity.

9. Conclusion

Advanced high pressure plunger pumps are indispensable tools in various industries, delivering reliable performance and efficiency. By understanding their mechanisms, key components, benefits, and maintenance practices, industry professionals can maximize the potential of these vital machines. Proper care and troubleshooting can extend their lifespan and ensure consistent operational success.

10. Frequently Asked Questions

10.1 What is a high pressure plunger pump?

A high pressure plunger pump is a type of positive displacement pump that uses a plunger to generate high fluid pressures, making it suitable for various industrial applications.

10.2 What industries commonly use high pressure plunger pumps?

These pumps are widely used in industries such as oil and gas, chemical processing, and water jet cutting due to their efficiency and durability.

10.3 How do I maintain a high pressure plunger pump?

Regular inspections, lubrication of moving parts, and cleaning to prevent contamination are essential maintenance practices to ensure the pump's longevity.

10.4 What are the benefits of using high pressure plunger pumps?

The benefits include high efficiency, durability, and precise fluid delivery, making them ideal for demanding applications.

10.5 What should I do if my pump is experiencing low pressure output?

Check for valve malfunctions or wear in the plunger. Inspecting and replacing these components can help restore proper function.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.