Advanced High Pressure Plunger Pumps: A Comprehensive Guide for Engineers

Table of Contents

- 1. Introduction to High Pressure Plunger Pumps

- 2. Understanding the Components of High Pressure Plunger Pumps

- 3. Operational Principles of High Pressure Plunger Pumps

- 4. Applications of High Pressure Plunger Pumps in Industry

- 5. Advantages of Using High Pressure Plunger Pumps

- 6. Maintenance and Troubleshooting of High Pressure Plunger Pumps

- 7. Future Trends in High Pressure Plunger Pump Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to High Pressure Plunger Pumps

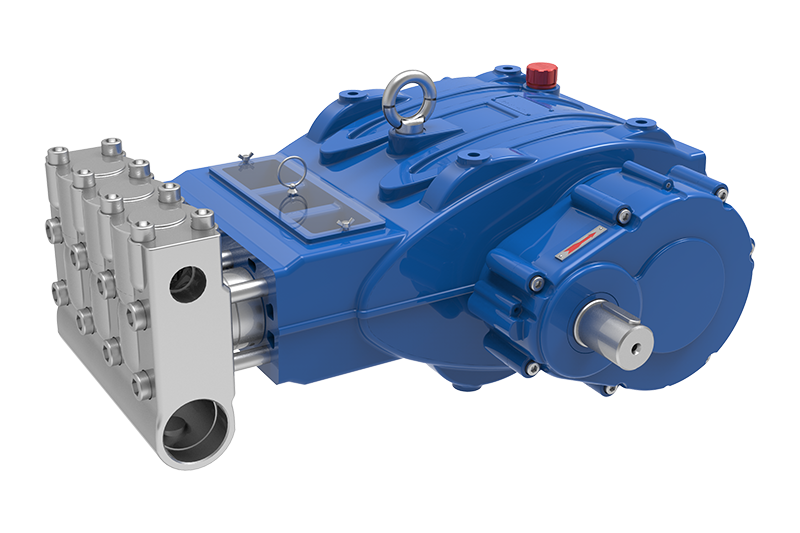

High-pressure plunger pumps play a vital role in various industrial applications where fluid delivery is critical. These pumps are specifically designed to handle high viscosity fluids and operate under high pressure, making them indispensable in sectors such as oil and gas, chemical processing, and water treatment. Understanding the complexities of these pumps is essential for engineers who aim to optimize their systems for efficiency and reliability.

2. Understanding the Components of High Pressure Plunger Pumps

To gain a comprehensive understanding of high-pressure plunger pumps, we must first examine their fundamental components.

2.1 Plunger

The **plunger** is the heart of the pump. It moves back and forth within the cylinder, creating a pressure differential that facilitates fluid movement. The choice of material for the plunger is crucial, as it must withstand high pressures and corrosive environments.

2.2 Cylinder

The **cylinder** houses the plunger, and its design is optimized for minimal friction. It is typically made from materials that offer durability and resistance to wear and tear, ensuring longevity and reliability.

2.3 Valves

**Inlet and outlet valves** control the flow of fluids into and out of the pump. These components need to be carefully designed to prevent cavitation and ensure smooth operation.

2.4 Drive Mechanism

The **drive mechanism** is responsible for converting rotary motion into linear motion to move the plunger. This can be achieved through various means, including electric motors or hydraulic systems.

3. Operational Principles of High Pressure Plunger Pumps

The operation of high-pressure plunger pumps is based on the principle of displacement.

3.1 Displacement Mechanism

When the plunger moves down, it creates a vacuum that allows fluid to enter through the inlet valve. As the plunger moves upward, the fluid is forced out through the outlet valve. This continuous cycle allows for a consistent flow of fluid at high pressures.

3.2 Pressure Generation

The high-pressure capability of these pumps is attributed to the reduction of volume within the cylinder as the plunger moves. By optimizing the plunger’s stroke length and speed, engineers can enhance the pump's pressure output.

4. Applications of High Pressure Plunger Pumps in Industry

High-pressure plunger pumps are versatile and find use in multiple applications across various industries.

4.1 Oil and Gas Industry

In the oil and gas sector, these pumps are utilized for enhanced oil recovery and in the transportation of viscous fluids under high pressure.

4.2 Chemical Processing

Chemical plants rely on high-pressure plunger pumps for the accurate dosing of chemicals, ensuring safe and efficient operations.

4.3 Water Treatment

In water treatment facilities, these pumps are crucial for the high-pressure delivery of water and chemicals used in purification processes.

4.4 Food and Beverage Industry

High-pressure plunger pumps are employed in the food and beverage industry for pasteurization and other high-pressure processing applications, ensuring product safety and quality.

5. Advantages of Using High Pressure Plunger Pumps

The benefits of using high-pressure plunger pumps in various applications are numerous.

5.1 Efficiency

High-pressure plunger pumps are known for their efficiency, capable of delivering high flow rates with minimal energy consumption. This efficiency translates to cost savings for industrial operations.

5.2 Reliability

The robust design of high-pressure plunger pumps ensures reliability over long periods, reducing the need for frequent maintenance and replacements.

5.3 Versatility

These pumps can handle a wide range of fluids, including corrosive and viscous materials, making them suitable for various applications across different industries.

5.4 Precise Control

Engineers appreciate the precise control offered by high-pressure plunger pumps, allowing for accurate dosing and fluid delivery.

6. Maintenance and Troubleshooting of High Pressure Plunger Pumps

To ensure optimal performance, routine maintenance and troubleshooting are essential.

6.1 Regular Inspections

Conducting regular inspections of the pump components helps identify potential issues before they escalate into significant problems. Checking for wear on the plunger, cylinder, and valves is vital.

6.2 Lubrication

Proper lubrication of moving parts reduces friction and prevents premature wear. Selecting the right lubricant is crucial based on the operating environment and fluid characteristics.

6.3 Troubleshooting Common Issues

Engineers should be prepared to troubleshoot common issues such as cavitation, excessive noise, and pressure fluctuations. Understanding the root causes of these problems can enhance the pump's longevity.

7. Future Trends in High Pressure Plunger Pump Technology

The field of high-pressure plunger pump technology is continuously evolving.

7.1 Smart Technologies

The integration of smart technologies, including IoT sensors and real-time monitoring systems, is transforming pump management and performance optimization.

7.2 Improved Materials

Ongoing research into advanced materials promises to enhance the durability and efficiency of plunger pumps, allowing them to withstand harsher operating conditions.

7.3 Energy Efficiency Standards

As industries strive for sustainability, new energy efficiency standards are being developed, pushing manufacturers to innovate and improve pump designs.

8. Frequently Asked Questions

8.1 What is a high-pressure plunger pump?

A high-pressure plunger pump is a type of positive displacement pump designed to generate high pressure for fluid delivery, making it ideal for various industrial applications.

8.2 How does a plunger pump work?

A plunger pump works by moving a plunger inside a cylinder, creating a pressure differential that allows fluid to enter and exit the pump through valves.

8.3 What are the common applications of high-pressure plunger pumps?

Common applications include oil and gas extraction, chemical processing, water treatment, and food and beverage production.

8.4 How do I maintain a high-pressure plunger pump?

Regular inspections, proper lubrication, and monitoring for common issues are essential for maintaining a high-pressure plunger pump.

8.5 What are the advantages of using high-pressure plunger pumps?

Advantages include high efficiency, reliability, versatility, and precise control over fluid delivery.

9. Conclusion

Advanced high-pressure plunger pumps are crucial components in a variety of industrial applications, offering efficiency, reliability, and versatility. Understanding their design, operation, applications, and maintenance is essential for engineers aiming to optimize performance. As technology evolves, staying informed about advancements in pump design and operation will be essential for maximizing productivity and efficiency in industrial processes. By investing time in understanding high-pressure plunger pumps, engineers can ensure they are equipped to make informed decisions that enhance their systems and contribute to overall operational success.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.