One of the primary advantages of using durable high pressure booster pumps is their ability to effectively manage high-pressure needs in a variety of systems. In many industrial processes, maintaining the correct pressure is crucial for operational efficiency and safety. These pumps are capable of delivering substantial energy boosts to fluids, ensuring that they reach their destination with the required pressure levels. This is particularly important in systems where gravity alone cannot provide the necessary force, or where long distances must be covered.

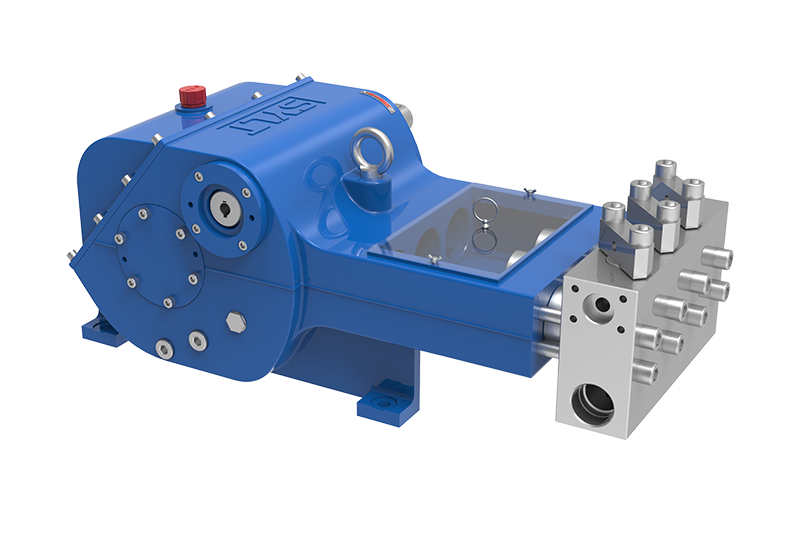

Durability is a key characteristic of these pumps. Constructed from high-quality materials, they are designed to resist wear and tear, which is essential in environments where they are exposed to corrosive substances or extreme temperatures. This longevity not only reduces maintenance costs but also allows for uninterrupted operation, which is critical in industrial processes that cannot afford downtime.

The versatility of durable high pressure booster pumps is evident in their wide range of applications. They are commonly used in reverse osmosis systems for water purification, in irrigation systems to maintain consistent pressure, and in fire suppression systems to ensure adequate water flow during emergencies. Additionally, these pumps are essential in various manufacturing processes where precise fluid control is needed.

When selecting a high pressure booster pump, it is important to consider factors such as flow rate, pressure requirements, and the type of fluid being pumped. A careful assessment of these parameters will help ensure that the chosen pump meets the specific needs of your application. Moreover, understanding the maintenance requirements can also help prolong the life of the pump, enhancing its performance over time.

In conclusion, durable high pressure booster pumps play a crucial role in a variety of industrial settings by enhancing pressure management and ensuring operational efficiency. Their robust construction and versatility make them an invaluable asset in any industrial pumping system. Whether for water treatment, irrigation, or manufacturing processes, the right pump can significantly impact performance and reliability. Always consult with professionals or conduct thorough research to choose a pump that best fits your needs, ensuring optimal results for your operations.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.