Understanding High Pressure Pumps: The Advantages of Low Flow Solutions

Table of Contents

- 1. Introduction to High Pressure Pumps

- 2. What are Low Flow Solutions?

- 3. The Mechanism of High Pressure Pumps

- 4. Advantages of Low Flow Solutions in High Pressure Systems

- 4.1 Enhanced Efficiency and Performance

- 4.2 Energy Savings and Cost Reduction

- 4.3 Increased System Longevity

- 5. Applications of High Pressure Low Flow Pumps

- 6. Choosing the Right High Pressure Pump

- 7. Maintenance Best Practices for High Pressure Pumps

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to High Pressure Pumps

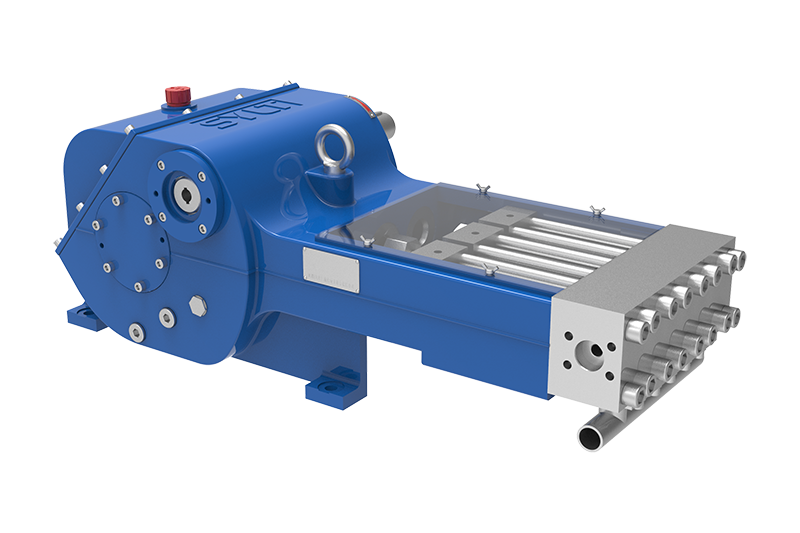

High pressure pumps play a crucial role in various industrial applications, delivering liquids and gases at elevated pressures. These pumps are designed to handle a wide range of fluids, from water and chemicals to slurries and viscous materials. Understanding the intricacies of high pressure pumps is essential for optimizing processes in sectors such as manufacturing, petrochemicals, and food processing.

The operational efficiency of these pumps can be significantly enhanced by integrating low flow solutions, which offer tailored performance benefits. As industries continue to strive for more efficient and sustainable operations, the demand for high pressure low flow pumping systems is rapidly increasing.

2. What are Low Flow Solutions?

Low flow solutions refer to pumping systems designed to operate effectively at lower flow rates while maintaining high pressure. These systems are engineered to deliver precise amounts of fluid, making them ideal for applications where accuracy and control are paramount.

Low flow pumps are characterized by their ability to minimize fluid wastage, reduce energy consumption, and provide stable pressure outputs. They are particularly valuable in scenarios where variable flow rates are required, enabling industries to adapt to changing demands without compromising system performance.

3. The Mechanism of High Pressure Pumps

High pressure pumps utilize different mechanisms to achieve elevated pressures, including positive displacement and dynamic pumping principles. Positive displacement pumps capture a fixed amount of fluid and discharge it at a higher pressure. In contrast, dynamic pumps use rotational energy to increase fluid velocity and pressure.

The choice of mechanism often depends on the type of fluid being pumped and the specific application requirements. Regardless of the mechanism, the integration of low flow solutions enhances these pumps' operational capabilities, providing benefits such as reduced wear and tear, lower energy costs, and improved system reliability.

4. Advantages of Low Flow Solutions in High Pressure Systems

Integrating low flow solutions in high pressure pumping systems offers several advantages that can significantly impact operational efficiency and cost-effectiveness.

4.1 Enhanced Efficiency and Performance

One of the primary benefits of low flow solutions is the enhanced efficiency they provide. By delivering precise volumes of fluid at high pressures, these systems minimize the risk of over-pumping and wasted resources. This level of efficiency translates into better performance metrics across various applications, from chemical processing to water treatment.

4.2 Energy Savings and Cost Reduction

Energy consumption is a critical factor in operating costs for industrial systems. Low flow solutions optimize energy use by ensuring that pumps operate only as needed, reducing the overall energy footprint. This not only cuts costs but also contributes to environmental sustainability efforts, aligning with the growing demand for greener industrial practices.

4.3 Increased System Longevity

Operating at lower flow rates can significantly reduce the stress on pump components, leading to increased system longevity. Less wear and tear prolongs the life of vital components, reducing the frequency of maintenance and replacement. This reliability is crucial for industries that require uninterrupted operations, as it minimizes downtime and enhances productivity.

5. Applications of High Pressure Low Flow Pumps

High pressure low flow pumps find applications across numerous industries, each benefiting from their unique features.

- **Chemical Manufacturing**: Precise fluid delivery is essential for chemical reactions, making low flow solutions a popular choice in this sector.

- **Oil and Gas**: In extraction and processing, maintaining consistent pressures while managing low flow rates can optimize production efficiency.

- **Water Treatment**: These pumps effectively manage the delivery of chemicals for water purification, providing necessary control over flow rates.

- **Food Processing**: Ensuring the hygiene and safety of processed foods requires reliable pumping solutions, making low flow systems ideal for this industry.

6. Choosing the Right High Pressure Pump

Selecting the appropriate high pressure low flow pump involves several considerations, including flow rate requirements, pressure ratings, and the nature of the fluid being pumped. Factors such as temperature, viscosity, and chemical compatibility will affect the choice of materials and pump design.

Working closely with manufacturers or distributors can help identify the best solutions tailored to specific operational needs. Additionally, evaluating the total cost of ownership, including energy consumption and maintenance costs, will provide a clearer picture of the pump's long-term value.

7. Maintenance Best Practices for High Pressure Pumps

Maintaining high pressure pumps is critical for ensuring their longevity and operational efficiency. Here are some best practices:

- **Regular Inspections**: Periodically check for leaks, wear and tear, and proper alignment.

- **Fluid Quality Monitoring**: Ensure that fluids being pumped meet the required specifications to prevent damage.

- **Routine Servicing**: Schedule regular maintenance with qualified personnel to address potential issues before they escalate.

- **Keeping Records**: Maintain detailed logs of maintenance activities and performance metrics to identify trends and areas for improvement.

8. Frequently Asked Questions

What is the primary advantage of low flow high pressure pumps?

The primary advantage is their ability to deliver precise volumes of fluid at high pressures, leading to enhanced efficiency and lower energy costs.

How do I know if a low flow pump is suitable for my application?

Consider factors such as the required flow rate, pressure ratings, and fluid characteristics. Consulting with pump manufacturers can provide valuable insights tailored to your specific needs.

Are low flow solutions more energy-efficient than traditional high flow pumps?

Yes, low flow solutions are designed to optimize energy use, reducing operational costs and the environmental impact compared to traditional high flow systems.

What industries benefit most from high pressure low flow solutions?

Industries such as chemical manufacturing, oil and gas, water treatment, and food processing find significant advantages in using high pressure low flow pumps for their specific applications.

How can I prolong the lifespan of my high pressure pump?

Regular maintenance, monitoring fluid quality, and following the manufacturer's guidelines for operation can significantly extend the lifespan of your high pressure pump.

9. Conclusion

High pressure pumps equipped with low flow solutions are revolutionizing industrial applications by enhancing efficiency, reducing energy consumption, and prolonging equipment lifespan. As industries strive to improve their operational practices, the integration of these advanced pumping systems will become increasingly important. Understanding the benefits and applications of high pressure low flow solutions empowers businesses to make informed decisions, paving the way for more sustainable and effective industrial operations. By adopting these innovative technologies, industries can optimize their processes and achieve long-term success in a competitive landscape.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.