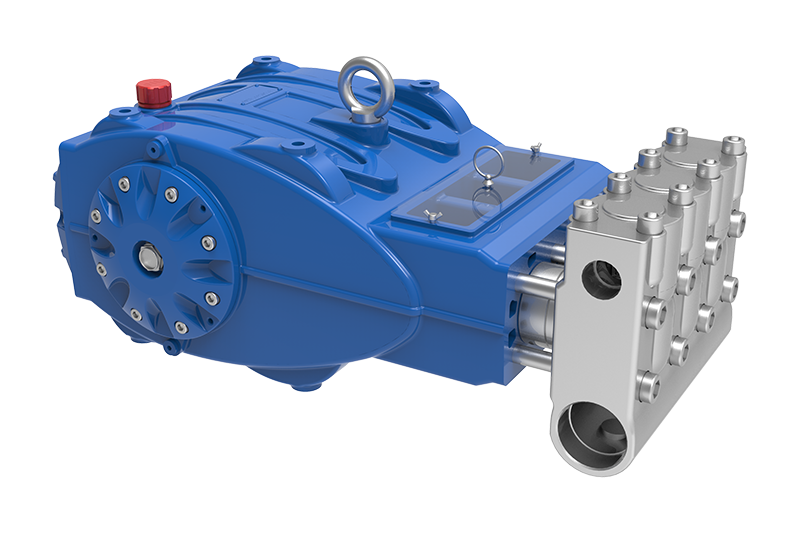

One of the primary advantages of high pressure plunger pumps is their ability to generate significant pressure levels, often exceeding 3000 psi (pounds per square inch). This capability makes them ideal for applications requiring precise fluid delivery and high force, such as in water jet cutting, oil and gas extraction, and chemical processing. The robustness of these pumps allows them to handle a wide range of fluids, including corrosive chemicals and viscous substances, offering versatility across different industries.

In terms of construction, high pressure plunger pumps typically feature durable materials that withstand extreme conditions. Components such as plungers, cylinders, and seals are often made from hardened materials to prevent wear and extend the pump's operational lifespan. Regular maintenance and careful monitoring of these components are crucial to ensure optimal performance and prevent potential breakdowns.

Moreover, high pressure plunger pumps are known for their energy efficiency compared to other pump types. Since they are designed to operate at high pressure with minimal energy loss, they can contribute to lower operational costs over time. Additionally, many modern plunger pumps are equipped with advanced control systems that allow for precise adjustments in flow rates and pressures, enhancing their adaptability in dynamic industrial environments.

High pressure plunger pumps find applications across various sectors, including manufacturing, agriculture, and automotive industries. For instance, in the automotive sector, they are often employed for fuel injection systems where precise delivery of fuel is critical for optimal engine performance. In the manufacturing realm, these pumps are essential for processes like surface cleaning and coating, where high-pressure streams effectively remove contaminants or apply coatings uniformly.

In conclusion, understanding the functionality and applications of high pressure plunger pumps is vital for professionals in the industrial equipment sector. By leveraging their efficiency and reliability, businesses can enhance their operational capabilities and meet the demands of various applications. Whether in manufacturing, energy, or chemical processing, high pressure plunger pumps remain a cornerstone of modern industrial operations, driving innovation and efficiency across the board.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.