Why High Pressure Water Jet Pumps are Essential for Efficient Cleaning Solutions

Cleaning is an integral part of maintaining the functionality and aesthetics of various industries, from manufacturing to construction. When it comes to effective cleaning, **high pressure water jet pumps** stand out as an essential tool. In this comprehensive guide, we will explore the importance of these pumps in achieving efficient cleaning solutions.

Understanding High Pressure Water Jet Pumps

High pressure water jet pumps utilize high-pressure water streams to remove dirt, grease, and other contaminants from surfaces. Unlike traditional cleaning methods, which may rely on brushes, chemicals, or manual labor, these pumps deliver focused streams of water that can tackle even the toughest cleaning tasks with ease.

How Do High Pressure Water Jet Pumps Work?

At the core of every high pressure water jet pump is a powerful motor that pressurizes water to create a concentrated jet. This jet is then directed through a nozzle, which determines the spray pattern and intensity. The high velocity of the water stream allows it to penetrate surfaces and dislodge debris effectively.

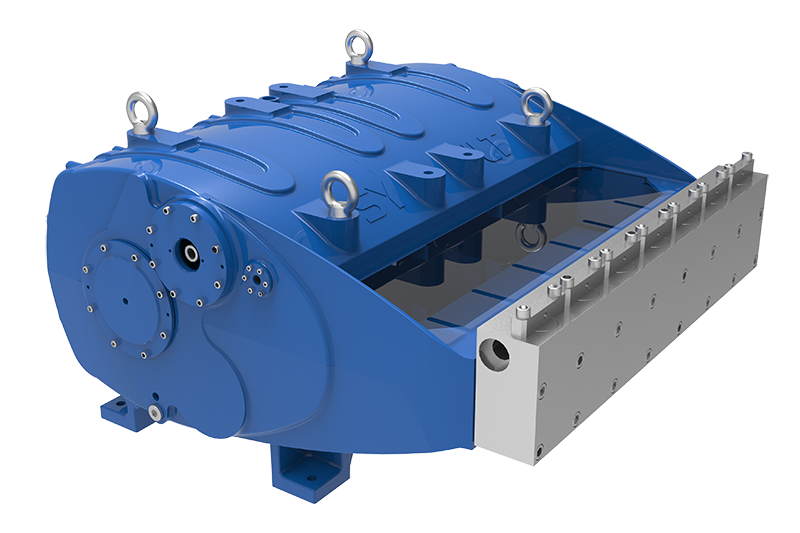

Components of High Pressure Water Jet Pumps

To fully appreciate the functionality of high pressure water jet pumps, it's essential to understand their key components:

- **Pump**: The heart of the system, responsible for pressurizing the water.

- **Motor**: Powers the pump, determining the pump's overall performance.

- **Hoses**: Durable hoses withstand high pressure, delivering water to the nozzle.

- **Nozzles**: Various nozzle types cater to different cleaning applications, altering the spray angle and pressure.

- **Filters**: Prevent debris from entering the pump, prolonging its lifespan.

The Importance of High Pressure Water Jet Pumps in Cleaning Solutions

High pressure water jet pumps offer numerous benefits that make them essential for efficient cleaning solutions across various industries.

1. Superior Cleaning Power

The concentrated water jets produced by high pressure pumps can remove stubborn stains, grease, and grime that traditional cleaning methods often struggle with. This superior cleaning power makes them ideal for applications such as:

- **Industrial facilities**: Cleaning heavy machinery and factory floors.

- **Construction sites**: Removing concrete residue and dirt from tools and vehicles.

- **Food processing**: Ensuring hygiene by eliminating bacteria and contaminants from surfaces.

2. Eco-Friendly Cleaning Solution

High pressure water jet pumps primarily use water for cleaning, reducing the reliance on harsh chemicals that can harm the environment. This eco-friendly approach not only protects the surroundings but also minimizes the risk of chemical exposure for workers.

3. Cost-Effectiveness

Although the initial investment in high pressure water jet pumps may be significant, the long-term benefits far outweigh the costs. **Reduced labor time**, **lower chemical usage**, and **minimal water waste** contribute to overall cost savings. Moreover, these pumps can handle multiple cleaning tasks, enhancing their utility and value.

4. Versatility in Applications

High pressure water jet pumps are not confined to one specific use; they can be employed in various settings, including:

- **Automotive maintenance**: Cleaning engine parts and exterior surfaces.

- **Ship cleaning**: Removing barnacles and marine growth from hulls.

- **Pipeline maintenance**: Clearing blockages and buildup in industrial pipelines.

Choosing the Right High Pressure Water Jet Pump

Selecting the right high pressure water jet pump involves considering several factors to ensure optimal performance for your specific cleaning needs.

1. Pressure Rating

The pressure rating, measured in PSI (pounds per square inch), determines the cleaning effectiveness. For heavy-duty applications, look for pumps with a high PSI rating to tackle tough jobs efficiently.

2. Flow Rate

The flow rate, measured in gallons per minute (GPM), indicates how much water is delivered through the pump. A higher flow rate allows for quicker cleaning, particularly in larger areas.

3. Portability

Depending on the application, portability may be a crucial factor. Some high pressure water jet pumps are stationary, while others are designed for mobility, making them suitable for various job sites.

4. Nozzle Options

Different nozzles provide varying spray patterns and pressure levels. Consider the specific cleaning tasks you'll undertake to choose a pump with the appropriate nozzle options.

Maintenance Tips for High Pressure Water Jet Pumps

To ensure longevity and optimal performance, regular maintenance of high pressure water jet pumps is essential.

1. Regular Inspection

Frequent inspections can identify potential issues before they escalate. Check hoses for wear and tear, and ensure connections are secure.

2. Cleaning Filters

Dirty filters can hinder performance. Clean or replace filters regularly to maintain efficient water flow and protect the pump from debris.

3. Proper Storage

When not in use, store your high pressure water jet pump in a dry, cool place. Protect it from extreme temperatures and moisture to prevent damage.

4. Follow Manufacturer Guidelines

Adhering to the manufacturer's maintenance guidelines can help ensure optimal performance and longevity. Regular servicing and adherence to recommended practices are key.

Common Applications of High Pressure Water Jet Pumps

High pressure water jet pumps are utilized across a myriad of industries, demonstrating their versatility and efficiency.

1. Industrial Cleaning

In industrial settings, these pumps are indispensable for cleaning machinery, tools, and factory floors. They effectively remove oil, grime, and other contaminants, ensuring a safe and productive work environment.

2. Surface Preparation

Before painting or applying coatings, high pressure water jet pumps prepare surfaces by removing old paint, rust, and other residues. This ensures a smooth application and extends the life of the coating.

3. Environmental Cleanup

In environmental restoration projects, these pumps can assist in cleaning up hazardous spills and contaminants from soil and water. Their ability to target specific areas without damaging surrounding environments is invaluable.

Efficiency and Productivity with High Pressure Water Jet Pumps

Implementing high pressure water jet pumps can significantly boost efficiency and productivity in cleaning operations.

1. Reduced Downtime

With faster cleaning capabilities, businesses can minimize downtime and maintain productivity levels. High pressure water jet pumps streamline cleaning processes, allowing operations to resume quickly.

2. Enhanced Worker Safety

By reducing the need for manual scrubbing and chemical use, high pressure water jet pumps contribute to a safer work environment. Workers are less exposed to hazardous substances, and the risk of injuries from manual labor is diminished.

Conclusion

High pressure water jet pumps are essential tools for achieving effective and efficient cleaning solutions across various industries. Their superior cleaning power, eco-friendliness, cost-effectiveness, and versatility make them indispensable in modern cleaning applications. By understanding their functionality, choosing the right model, and implementing proper maintenance, businesses can unlock the full potential of these pumps to enhance productivity and maintain a clean, safe environment.

Frequently Asked Questions (FAQs)

1. What is the ideal pressure for high pressure water jet pumps?

The ideal pressure depends on the specific cleaning task. Generally, pressures between 2,000 to 4,000 PSI are suitable for most industrial applications, while more challenging tasks may require even higher pressures.

2. Can high pressure water jet pumps be used for home cleaning?

Yes, high pressure water jet pumps can be used for various home cleaning tasks, including driveway cleaning, patio restoration, and exterior house washing.

3. Are high pressure water jet pumps safe to use?

When used correctly and with appropriate safety gear, high pressure water jet pumps are safe. Operators should follow manufacturer guidelines and wear protective equipment to ensure safety.

4. How often should I service my high pressure water jet pump?

Regular maintenance is crucial for optimal performance. It's recommended to inspect and service the pump at least once a year or more frequently if used heavily.

5. What types of cleaning tasks are high pressure water jet pumps best suited for?

These pumps are ideal for removing stubborn stains, grease, and grime from industrial machinery, vehicles, surfaces, and more, making them versatile for multiple applications.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.