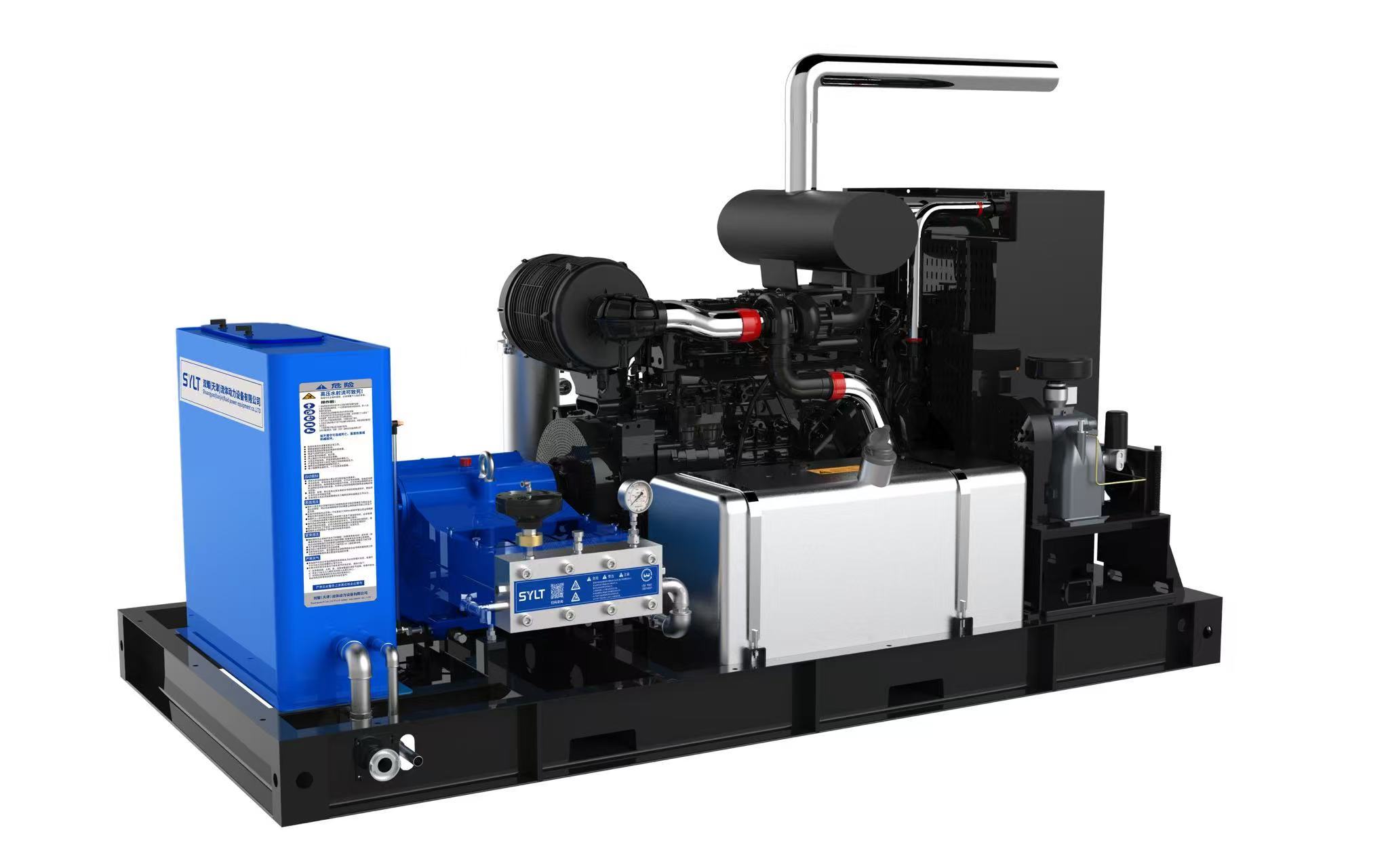

As the “heart” of the high-pressure cleaning system for reaction vessels, the technical performance of the high-pressure plunger pump directly determines the cleaning effectiveness. Below is an analysis of its core technologies and key application points.

💎 Core Features and Technical Principles

In reactor cleaning, the core function of a high-pressure plunger pump is to boost ordinary-pressure water to ultra-high pressure (such as 2800 bar), generating a high-speed water jet with tremendous impact energy. This jet stream passes through... Peeling, cutting, and impact Its synergistic effect can effectively remove stubborn dirt from the inner walls of the reactor and the surfaces of the agitator without damaging the metal substrate.

📊 Technical Specifications and Selection Comparison

To clean dirt of varying hardness and thickness, it is necessary to select plunger pumps with different pressure levels. Below is a comparison of the technical parameters and application scenarios for three typical pressure levels:

| Technical Parameters / Application Scenarios | General-purpose cleaning (100-200 MPa) | High-pressure cleaning (200-280 MPa) | Ultra-high-pressure cleaning (280 MPa and above) |

|---|---|---|---|

| Typical pressure range | 100 - 200 MPa | 200 - 280 MPa | ≥ 280 MPa (2800 bar) |

| Typical flow range | 40 - 93 L/min | 40 - 85 L/min | 40 - 530 L/min (depending on the specific model) |

| Drive power | 90 - 160 kW | Approximately 255 kW | 252 - 450 kW or higher |

| Main applications | Common scale, chemical residues, and general carbon deposits | Hard scale, polymer residue, moderate coking | Extremely stubborn polymers, thick-layer heavy oil coke, mixed metal salt deposits |

| Technical Features | Cost-effective and capable of meeting most chemical reactor cleaning needs. | Balances pressure and flow, with wide applicability. | The ultimate physical cleaning method, which may also incorporate cutting functionality, places extremely high demands on both the equipment and the operator. |

Note: Before applying ultra-high pressure of 2800 bar, Must Professionally assess the pressure-bearing capacity and current condition of the reactor vessel itself to prevent damage to the equipment.

🔧 Key Component and System Integration

A complete cleaning system, in addition to the pump, also requires other key components to work together:

Power end and hydraulic end The power end (crankshaft and connecting rod) provides the driving force, while the hydraulic end (plunger, seals, and valve assembly) achieves water pressurization and delivery. Some pump heads are made of corrosion-resistant materials (such as titanium alloy) to withstand chemical cleaning solutions.

Implementing agency Typically connected to a 3D rotary nozzle or cleaning arm, it can cover the inner wall of the reactor with 720° coverage, leaving no dead angles.

Control system Modern systems often employ PLC-based fully automatic control with pre-set cleaning paths, enabling unmanned operation.

🛡️ Key Points for Safe Operation and Maintenance

Operational safety : Establish Quarantine zone Operators must undergo specialized training and wear a full set of protective equipment. Under no circumstances is pressure maintenance allowed.

Equipment maintenance Regularly inspect vulnerable components such as plunger seals and the inlet/outlet valve assemblies; ensure that the lubrication and cooling systems are functioning properly; and use filtered water to reduce wear inside the pump.

System compatibility Ensure that the pump’s rated pressure and flow rate are compatible with the subsequent piping, nozzles, and actuators.

💡 Selection and Evaluation Recommendations

Dirt Rating First, analyze the composition of the dirt and its adhesion strength, then refer to the table above to determine the required pressure level, thereby avoiding both “overperformance” and “insufficient cleaning.”

Professional services For ultra-high-pressure cleaning at the 2800 bar level, it is strongly recommended to hire a qualified professional service company that can provide equipment, operators, and comprehensive safety insurance.

Comprehensive Assessment In addition to pressure, it’s also necessary to comprehensively consider flow rate, equipment power, material compatibility, and the degree of automation.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.