1. Introduction to High Pressure Water Jet Pumps

In today's fast-paced industrial landscape, the demand for efficient and versatile equipment is paramount. One of the most significant advancements in pumping technology is the **high pressure water jet pump**. These pumps utilize high-pressure water to perform a variety of tasks, from cutting and cleaning to material removal. As industries evolve, understanding the importance and functionality of these pumps becomes critical for maintaining competitive advantage.

2. The Technology Behind High Pressure Water Jet Pumps

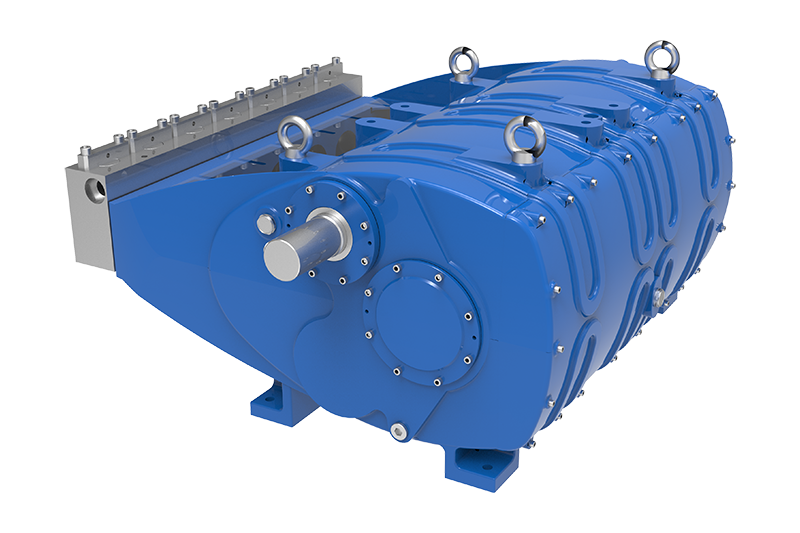

High pressure water jet pumps operate by converting mechanical energy into high-pressure water streams using a variety of technologies. The core components include:

- **Electric or diesel engines** that power the pump mechanism.

- **Pressure intensifiers** that increase the water pressure to levels that can exceed 40,000 psi.

- **Nozzles** designed for specific applications, allowing for precise control of the water jet.

This technology not only enables the equipment to perform tasks with remarkable precision but also contributes to reduced wear and tear on the machinery.

3. Key Benefits of Using Advanced High Pressure Water Jet Pumps

3.1 Increased Efficiency in Industrial Processes

One of the leading advantages of high pressure water jet pumps is their ability to **enhance efficiency**. Whether it's cutting through metal or cleaning tough residues, these pumps deliver results faster than traditional methods. The high velocity of the water stream allows for swift material removal or surface preparation, significantly reducing operational downtime.

3.2 Cost-Effectiveness and Sustainability

High pressure water jet pumps are designed with energy efficiency in mind. By utilizing water as the primary medium, operations reduce reliance on chemical solvents and abrasive materials, leading to considerable cost savings. Additionally, the sustainability aspect cannot be overlooked—using water jets minimizes waste and environmental impact, making these pumps an eco-friendly choice.

3.3 Enhanced Safety Features

Safety is a cornerstone of any industrial operation. Advanced high pressure water jet pumps come equipped with features that promote a safer working environment. The enclosed system prevents accidental exposure to hazardous materials, while the precise control of water pressure minimizes risks associated with traditional abrasive cutting methods.

4. Diverse Applications of High Pressure Water Jet Pumps

The versatility of high pressure water jet pumps allows them to be utilized across various sectors:

4.1 Manufacturing and Fabrication

In manufacturing, these pumps are used for cutting metal components, shaping materials, and preparing surfaces for welding or coating. The precision of water jets leads to cleaner cuts with minimal thermal distortion, ensuring a higher quality end product.

4.2 Oil and Gas Industries

Within the oil and gas sector, high pressure water jet pumps are employed for pipeline cleaning, casing removal, and even well stimulation. Their ability to effectively clear blockages and debris makes them invaluable in maintaining operational efficiency.

4.3 Cleaning and Maintenance Operations

From industrial equipment to building facades, high pressure water jets serve an essential role in cleaning. They effectively remove grease, grime, and other contaminants without damaging the underlying surfaces, making them ideal for maintenance tasks across various applications.

5. Comparison with Traditional Pumping Solutions

When comparing high pressure water jet pumps to traditional pumping systems, several key differences emerge. Traditional pumps often rely on mechanical abrasion or chemical solvents, which can be less effective and more damaging to materials. In contrast, water jet technology offers a non-contact solution that reduces wear and tear on both the equipment and the materials being processed.

6. Selecting the Right High Pressure Water Jet Pump for Your Needs

Choosing the right high pressure water jet pump involves assessing specific operational requirements. Factors to consider include:

- **Pressure ratings**: Understanding the necessary pressure for your application.

- **Flow rate**: Determining the volume of water required for optimal performance.

- **Pump type**: Deciding between electric and diesel options based on environmental conditions and portability needs.

Consulting with industry experts can provide valuable insights into selecting the best pump for your unique operational needs.

7. Maintenance and Care for High Pressure Water Jet Pumps

Proper maintenance is crucial for the longevity and performance of high pressure water jet pumps. Key maintenance practices include:

- **Regular inspections** of all components to identify wear and damage.

- **Routine cleaning** of filters and nozzles to prevent blockages.

- **Scheduled servicing** to ensure all mechanical aspects are functioning smoothly.

By adhering to these practices, industries can ensure their high pressure water jet pumps remain reliable and efficient.

The adoption of advanced high pressure water jet pumps is not just a trend; it represents a fundamental shift in how industries approach efficiency, safety, and sustainability. As technology continues to evolve, the benefits of these pumps—including enhanced precision, reduced environmental impact, and cost savings—will only become more pronounced. For industries looking to stay ahead in a competitive market, investing in high pressure water jet pumps is not just an option; it's a necessity. Embrace the future of pumping technology and transform your operational capabilities today.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.