1. Introduction

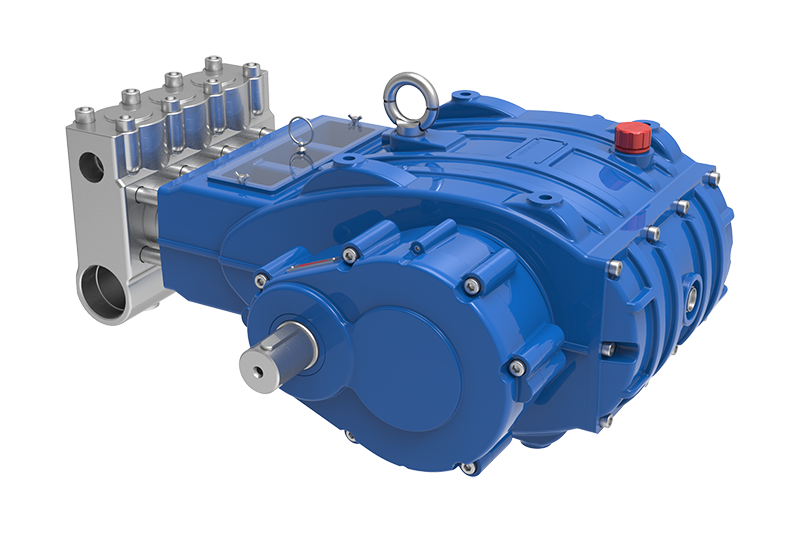

High pressure plunger pumps are designed to move fluids at high pressures, making them essential in various industrial applications. These pumps utilize a plunger mechanism to draw and expel liquids, allowing for precise control over flow rates and pressure. The newest models incorporate advanced technology, materials, and design features that enhance their performance and efficiency.

2. Key Features of the Newest High Pressure Plunger Pumps

2.1 Innovative Design and Engineering

The latest high pressure plunger pumps showcase innovative designs that improve usability and functionality. These pumps often feature:

- Compact Structures: New designs maximize space efficiency, allowing installation in tight areas.

- Modular Components: Simplified parts allow for easy replacement and upgrades, reducing downtime.

- Corrosion-Resistant Materials: Advanced materials extend the lifespan of pumps in aggressive environments.

2.2 Enhanced Efficiency and Performance

The efficiency of high pressure plunger pumps is crucial for achieving optimal performance. Recent advancements have led to:

- Higher Flow Rates: New designs can handle increased volumes without sacrificing pressure.

- Energy Efficiency: Modern pumps consume less energy, resulting in lower operational costs.

- Smart Technology Integration: Features like IoT connectivity enable real-time monitoring and adjustments.

3. Benefits of Using High Pressure Plunger Pumps

3.1 Reliability and Durability

Reliability is a critical factor in industrial operations. The newest high pressure plunger pumps are built to withstand rigorous conditions and provide consistent performance. Benefits include:

- Robust Construction: Engineered to handle high pressures without risk of failure.

- Longevity: Reduced wear and tear prolongs the lifespan, ensuring long-term investment value.

3.2 Low Maintenance Requirements

Maintenance is a significant concern for industrial facilities aiming to minimize downtime. The latest models emphasize low maintenance needs through design innovations:

- Self-Lubricating Systems: These systems reduce friction and the need for frequent servicing.

- Easy Access to Components: Maintenance is simplified, enabling quicker repairs and inspections.

4. Industrial Applications and Use Cases

High pressure plunger pumps find applications across various sectors, demonstrating their versatility and effectiveness. Key industrial applications include:

4.1 Chemical Processing

In chemical processing, high pressure plunger pumps are essential for transferring corrosive and viscous materials. They provide:

- Accurate Dosing: Essential for ensuring precise formulations.

- Safe Handling: Designed to manage hazardous materials effectively.

4.2 Water Treatment

Water treatment facilities leverage high pressure plunger pumps to ensure efficient filtration and purification processes. Their benefits include:

- Effective Filtration: Capable of handling high flow rates, ensuring clean water output.

- System Integration: Easily integrates with existing water treatment systems.

5. The Future of High Pressure Plunger Pump Technology

The future of high pressure plunger pump technology is bright, with ongoing advancements promising even greater efficiency and capabilities. Emerging trends include:

- Smart Pumps: Increased integration of smart technologies for enhanced control and monitoring.

- Sustainability: Focus on eco-friendly designs that minimize environmental impact.

- Customization: Tailored solutions to meet specific industrial needs, enhancing versatility.

The newest high pressure plunger pumps are undeniably game changers in the industrial sector. With their innovative design, enhanced efficiency, and versatility across multiple applications, these pumps are setting new standards for performance and reliability. As industries strive for greater operational efficiency and cost-effectiveness, embracing high pressure plunger pump technology is not just advantageous but essential. The future looks promising, with continued advancements ensuring these pumps will remain at the forefront of industrial innovation.

The 17th China International Powder Metallurgy and Hard Alloy Exhibition

The 2025 17th China International Powder Metallurgy and Hard Alloy Exhibition from March 10-12, 2025, at the Shanghai World Expo Exhibition and Convention Center, Hall H1, B425. We welcome guests to visit.

"Private custom" product design, reliable and durable finished products

"Private custom" like product design, reliable and durable finished products, professional and timely after-sales service. It is the "three basic concepts" that the company adheres to from the beginning until today ".

Experienced market research team, independent product development concept

We have experienced mature market research team, independent product research and development concept, professional design and manufacturing technology so that the company's products can be adjusted according to the specific requirements of customers timely design

Copyright©Shuangyao (Tianjin) Fluid Power Equipment Co., Ltd.